4.3 Air conditioning and environmental control

Air conditioning, environmental control, or building management technology are all terms used to describe systems of varying sophistication that control and manage the environment inside a building. Though such systems were developed principally for the comfort of the occupants of buildings, they are a necessity if the rooms are to meet the long-term storage conditions of the audiovisual collections as specified in this publication. In principle, air conditioning systems are the same whether they are used for preservation and storage or comfort purposes. However, air conditioning systems for collection and storage demand much tighter tolerances and much better control.

4.3.1 Temperature control. Temperature control is achieved through heating or cooling the air that is being blown into the environment to be controlled. Sensors in the room detect the conditions and this information is used to control the heating or cooling elements. The interaction with sensors raises some issues that are discussed below.

It is important to note that cooling is the act of removing heat from an area and transferring it to another environment.

An evaporative cooling system, which passes air through a moist environment and so removes heat energy through evaporation, has no place in an archive, partly because it increases the relative humidity. In any case, it is only effective in very dry environments.

A critical fact in the design of environmental control systems is that heating air reduces the relative humidity and cooling air increases the relative humidity. Stable temperature and stable humidity are both of importance and their control is linked: for this reason all temperature control must be coupled with humidity control (3.2.3).

4.3.2 Principles of dehumidification. Almost all storage environments will require dehumidification most of the time in order to remove moisture from the air and so comply with the conditions specified in this publication. The need for humidification, the addition of moisture to the air, is much more rare and, if needed, can be achieved fairly simply. Relative Humidity, which is the most common way to specify moisture in the air, is a percentage measure proportional to the amount of moisture the air could hold at a given temperature and pressure, the latter being dependent on altitude.

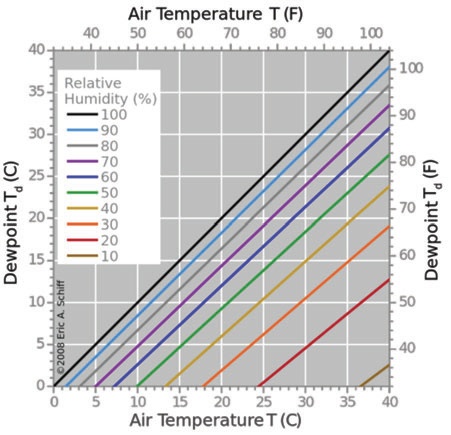

Dehumidification is the removal of moisture from the air to reduce the relative humidity. As was stated above, cooling air increases the relative humidity. If the temperature of the air is made lower it will eventually reach a point at which the moisture in the air condenses to form droplets of liquid. The temperature at which the moisture condenses is known as the “dew point”.

Figure 30: Table of dew point levels. (By Easchiff (own work) [CC-BY-SA-3.0-2.5-2.0-1.0 (http:// creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons)

The most common way to dehumidify an environment is to cool the air being treated to a temperature well below the dew point and, thus, remove moisture from the air as water droplets. The treated air is then heated to the required temperature and the resultant relative humidity is a product of the amount of moisture removed by cooling and the final temperature of the air being treated.

This approach though practical, simple and common, has a number of significant problems. Firstly, the energy cost in cooling and then reheating air is quite substantial and should be considered as a factor in the long term running of any environment. Secondly, the amount of moisture removed from the air is proportional to the temperature differential and a system will often have to be overdesigned in order to be suitable for a wide range of environmental conditions experienced in many places. This is a particular problem in cool environments. And finally, it is very difficult to get accurate control using these sorts of systems, which may lead to cycling such that the system constantly seeks to adjust the conditions and this leads to regular increases and decreases in temperature and humidity, which is in itself detrimental to the storage of collection material.

Desiccant dehumidification is the removal of moisture from the air within a storage area by using a substance (desiccant) that is able to absorb moisture. The desiccant is subsequently heated, outside the controlled area to remove the absorbed moisture after which it can be reused. Such systems can achieve the low levels of dehumidification required for archival storage in most environments and are more energy efficient than the common cooling and heating approach described above.

4.3.3 Sensors are the devices used to detect temperature humidity and other aspects of air quality and condition. Most sensors used in an office environment have tolerances of ±5% or greater. While this is adequate when controlling office environments, when used in critical systems such as archival storage they cannot achieve the tolerances specified in this document.

Sensors detect the conditions in the controlled environment and communicate that information to the air conditioning system. In its simplest form, when conditions are outside of those required, the system switches on; when they are within required conditions the system is turned off. When the system operates in this manner the conditions in the controlled environment can cycle between high and low which has an adverse effect on the materials being stored. In order to overcome this, modern systems with high quality sensors and control technology gradually switch in and out heating and cooling elements leading to a very stable storage environment.

It is common practice to place sensors in the flow of air being extracted from the storage area. However, a poorly designed system can result in pockets or spaces within the storage environment that may be out of specification but undetected by the system (microclimates). Multiple sensors are recommended, with an appropriate agreement on how the sensors are weighted in determining the room conditions.

4.3.4 Air quality and filtering. Air conditioning systems are generally designed to recycle the air in an environment by adding a pre-set proportion of fresh air from outside. The smaller the proportion of fresh air, the simpler and more cost-effective it is to maintain the required conditions. The amount of fresh air is a health issue and most countries have standards that specify a minimum figure of around 10% fresh air. Though storage environment could have a lower proportion of fresh air this would necessitate sensors to determine the build-up of carbon dioxide and other unwanted gases in the storage rooms. It is also likely that the plastics in the media being stored will give off gases, which would build up in such an environment. Therefore, figures near 10% are a suitable compromise between cost and clean air. The flow of air through the room must reach every part in order to prevent any localised build-up of contaminants.

Pumping treated area air into an environment will almost certainly lead to a build-up of dust and other airborne particulates. Air conditioning systems must have filters that remove those particulates. The type of filter and the size of the particulates it removes will depend on the quality of the air both inside and, particularly, outside the building. In addition to well-maintained filters, the amount of dust in an environment can be minimised by maintaining a higher pressure in the room compared to the surrounding area.

For storage areas and laboratories, clean room classes ISO 8, preferably ISO 7 according to ISO 14644-1 should be the target.25

The presence of sulphur dioxide, nitrogen dioxide and oxides of nitrogen, and other gaseous pollutants will degrade the life expectancy of the carriers stored in an environment. Most countries have a specification for air quality, and will recommend particular filter classes.

All filters require regular maintenance and cleaning in order for them to be effective.

25. ISO 8 equals clean room class 100.000 according to former US FED STD 209E, ISO 7 class 10.000.