Conditions for Storage and Treatment

Given the destructive role of airborne moisture in the decomposition of polymers used in magnetic tapes, the theoretical possibility of reversing the reaction, and the need to recover information from degraded tapes, investigations were conducted into low humidity rejuvenation. The first goal was to at least restore tapes to a playable condition so that they could be dubbed. The increasingly popular industry practice of baking tapes at up to 60°C was included in our study. An absolute ceiling is indicated by the glass transition temperature (Tg) for PET of around 70°C. It is quite possible that changes in crystallinity or chain mobility may occur at even moderately elevated temperatures, hence it is advisable to use caution when treating tapes in this manner.

Initial trials were conducted on expendable tape samples of various ages up to 12 years, some of which were already showing signs of hydrolysis - squealing, shedding gummy deposits, and SE of 4-5%. Musical and spoken-word programs and test tones were used to measure side effects such as print-through and scrape-flutter. Whilst some tapes recovered to a playable condition after 24 hours at 55°C and ambient humidity (air at 50% RH at 22°C drops to less than 10% RH when heated to 55°C), the recovery only lasted for a few weeks or months and side effects such as print-through and packing damage occurred.

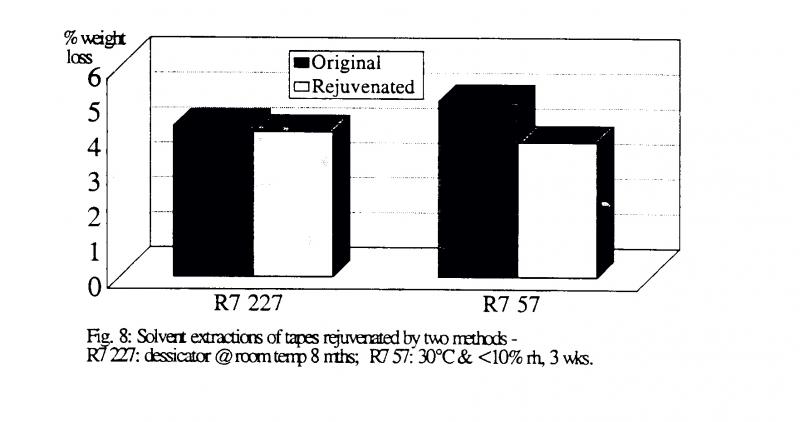

In order to try a more cautious method, a squeaky, shedding 7” original tape from the collection with SE of 4.3% was placed in a partially evacuated glass desiccator charged with barium oxide over a period of 8 months at room temperature (22°C ). The tape recovered from a state of squealing after a few minutes of playback with moderate shedding, to a point of playing from end to end (30 minutes) with no squeal and very slight shedding. The SE fell to 3.9%. At around the same time, a series of tapes in varying condition was treated for 3 weeks at 30°C and <10% RH. Most of the tapes recovered to a degree, although for some the improvement was slight rather than dramatic. We realised that patience and greater understanding would be needed to pursue the process further. A typical tape from this batch is shown in Fig.8, along with the earlier example.

Arrhenius equations can be used to help estimate time elapsed before failure or recovery in such reactions. A simplified model can be expressed as:

In LE = k/T

where LE equals life expectancy or time elapsed before failure/recovery, T equals temperature, and k is a rate constant based on the activation energy for a particular formulation, and the humidity of the storage or treatment environment. Rate constants from such projections suggested that longer times or higher temperatures were needed to restore many tapes to a more playable condition.

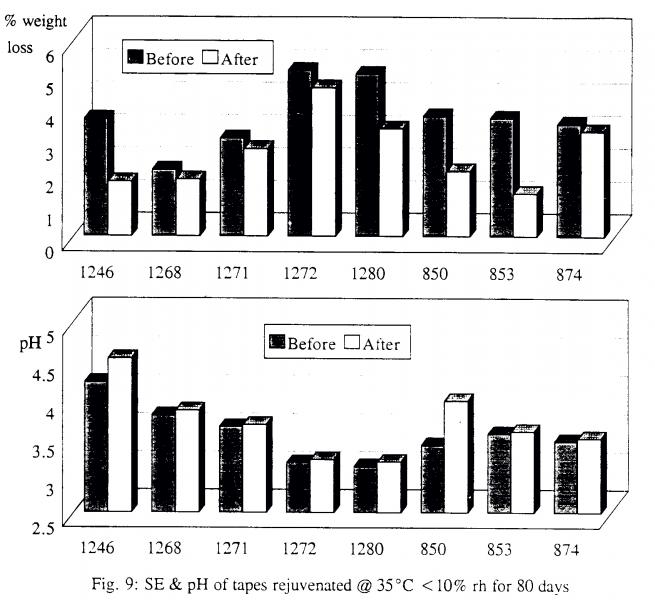

Our current program is based on a limited range of temperatures (usually around 35°C) with longer treatment times and very low RH (below 5%) regulated by means of chemical desiccant and/or thermo-mechanical (refrigerant) systems. Stable laboratory-type environmental and vacuum chambers are used to avoid pack stress or damage from fluctuating temperatures which typically occur in domestic ovens. Tapes treated in this manner show consistent improvement in key parameters. Fig.9 shows the results of SE and pH of representative samples from recently restored collections; the sequential shelf numbers appear along the x-axis. Significant recovery of most tapes took place over 6-10 weeks with further improvement after this time. Although some forward planning is necessary to organise workflow between the lab and studios to maintain rates of subsequent dubbing, the actual labour component for batch treatment and monitoring is not great.

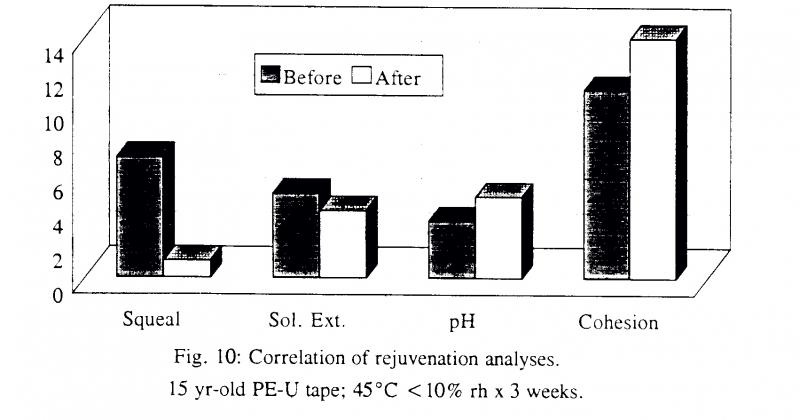

If tapes are needed in a hurry, a higher temperatures may be used, but we stop well short of ‘baking' tapes as is commonly advocated. At temperatures over 35°C tapes are normally interleaved with blank stock, separating layers to minimise print-through. Typical results for a fast-tracked tape are shown in Fig.10 which illustrates the correlation between key measurement parameters and playability. As well as SE and pH the graph shows the improvement in cohesion as previously described, and audibly-assessed squeal falling from 7 (pronounced after a few minute's playback) to 1 (barely discernible). Specialised cleaning and reproduction machinery may still be used on many tapes to ensure that faithful dubs are made.

It is understood that complete reversibility of decomposition may be limited by factors such as the migration of plasticisers, lubricants and other constituents including broken- down products of decomposition; secondary reactions, crosslinking or combinations of constituents forming different compounds to those originally present; changes in physical properties of tape over time.