2.1.1.2 Coarse groove discs (gramophone discs)

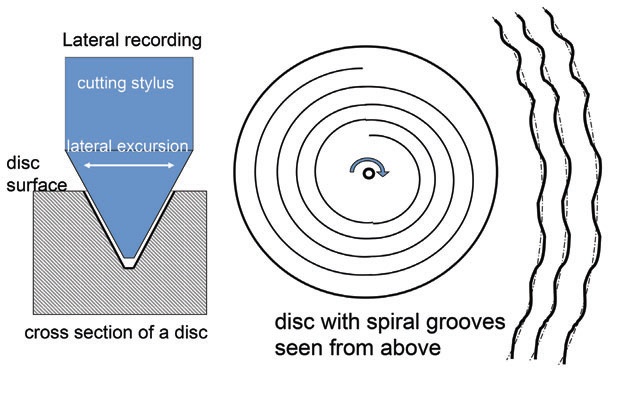

Emile Berliner invented the gramophone in 1887. The groove is arranged as a spiral on the surface of a disc. Generally, the modulation of the grooves is lateral, as opposed to vertical for cylinders. Only a few disc formats (Pathé, Edison) have vertically cut grooves. The big advantage of the disc shape, apart from greater ease of storage, is that galvanoplastic negatives can be easily made and used for replication by pressing. As the number of pressings is limited, the first metal negative (“father”) serves only as a master for a metal positive (“mother”), which is used to produce an unlimited numbers of metal stampers (“sons”), which are used for the pressing tools for the replicated discs. This method, established at the beginning of the 20th century, is still being used for micro groove discs (“vinyls”), and for the production of replicated CDs, DVDs and BDs.

Figure 4: Coarse and micro groove discs recording principle.

2.1.1.2.1 Replicated coarse groove discs. The majority of coarse groove discs — the so-called shellac records — consist of a mixture of mineral powders bonded together by binders, originally containing shellac resin. These materials are chemically generally very stable if kept under fairly dry conditions. They are, however, fragile: when dropped, they break. Apart from shellacs, other record types existed in much smaller quantities and used different materials. These were often of lesser stability, for example, Edison Diamond discs, which are extremely susceptible to moisture.5

2.1.1.2.2 Instantaneous discs were recording media that were widespread in radio stations, before the advent of magnetic tape. The discs were used to record and replay signals without the need for galvanoplastic processing and pressing. Their surfaces are soft enough to permit the cutting of the groove, but hard enough to permit a number of replays. Most of these discs are unique recordings. If not recognisable by their distinct appearance, almost all instantaneous discs can be identified by their handwritten or typed labels.

There are homogeneous discs made from one single material component such as aluminium, zinc, PVC, or gelatine, as well as laminated discs, which are composed of a substrate and a surface coating made from different materials that is engraved with the recording.

2.1.1.2.2.1 Lacquer discs. The most widespread type of instantaneous discs is laminated: the lacquer or “acetate” discs. A lacquer coating consisting mainly of cellulose nitrate and usually plasticized with castor oil or camphor carries the information. The substrate that supports the information layer of the discs is generally of metal (e.g. aluminium or zinc); some are of glass, cardboard, or paper.

Lacquer discs can be easily identified as the base material can usually be seen between the outer lacquer layers, either within the centre hole or at the disc edge (IASA-TC 04, 5.2.2.5).

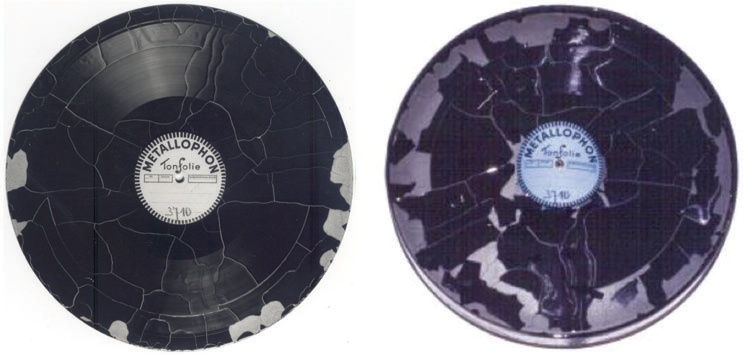

Cellulose nitrate decomposes continuously over time by reacting with water vapour or oxygen. This process produces acids that act as a catalyst for these hydrolytic reactions. Elevated temperature and humidity levels will further accelerate these reactions. Gradual degradation, along with loss of plasticisers, causes progressive embrittlement and shrinking of the lacquer coating. As the lacquer is bonded to a substrate that cannot shrink, internal stresses ultimately result in a cracking and flaking off of the lacquer coating, leading to the loss of the sound carrying layer. The mechanical instability of cardboard/paper bases often results in uneven or cracked surfaces while the fragility of glass bases often results in broken discs.

Figure 5: Metal based lacquer disc in the process of deterioration 1990–2001.

Figure 6: Cardboard based lacquer disc in the process of deterioration. (Stig-Lennard Molneryd)

Internal stresses are difficult to detect. Lacquer discs should not, therefore, be exposed to mechanical or thermal stresses. As their further life expectancy is unpredictable, the recordings on such discs should be immediately transferred to digital files before they are lost.

2.1.1.2.2.2 Other instantaneous discs. In addition to lacquer discs, all other instantaneous discs, irrespective of their particular composition, should also be considered to be at great risk.

5. For details of early coarse groove discs see St-Laurent 1996.