8.1.4 Recordable CD and DVD Description

8.1.4.1 CD-Rs and DVD-/+Rs store data in line with microscopic grooves running in a spiral from the centre of the disc to its periphery. All CD/DVD drive types use laser beams to scan these grooves. They differ in the wavelength of the laser beam: DVDs use a narrower track pitch of 0.74µm, compared to 1.6µm on CDs. DVD also takes advantage of new modulation and error correction methods not available when the CD was specified.

8.1.4.2 The mechanical dimension of CDs and DVDs are equal: 120mm in diameter, and 1.2 mm thick. The DVD, however, is made up of two discs of 0.6mm thickness, which are bonded together.

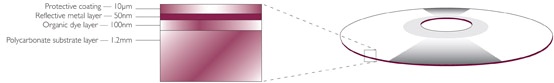

8.1.4.3 CD-R and DVD+R consist of three layers: the clear polycarbonate substrate, the dye layer and the reflective layer. In CD-R the reflective layer is close to the label side of the disc and an additional protective lacquer surface layer covers the fragile surface. DVD-Rs reflective layer is situated in the middle of two polycarbonate layers. In the recording process, a laser of much higher intensity than the reading laser “burns” the organic dye according to the coded signal, leaving a row of minuscule transparent and non-transparent areas aligned along grooves in the disc. All recordable CDs and DVDs contain a reflective layer that allows a reading laser to bounce off the CD/DVD and to be “read” by the pickup sensor in the CD or DVD replay device. Many metals are suitable for use as a reflective layer, although only two have been in widespread use on recordable CD and DVD, gold or silver. The combination of the recorded dye groove with the reflective layer modulates the reading laser in the same way as the injection moulded pits and lands and the reflective aluminium layer of a CD -ROM.

8.1.4.4 The three common organic dyes used in recordable discs are cyanine, phthalocyanine and azo. In a recordable CD each dye gives the media its distinctive look depending on which metal is used for the reflective layer; cyanine (blue) dye appears green on gold media and blue on silver media; phthalocyanine (clear light green) dye appears transparent on gold media, but light green on silver media; azo (deep blue) has developed into different shades of blue, the original being a deep blue, and the more recent Super Azo a brighter shade of blue. Because the dye layer is applied so thinly in recordable DVD the type of dye used on recordable DVDs is not easily distinguishable. However, manufacturers of recordable CD and DVD encode information about the type of dye in the polycarbonate layer. The CD and DVD burners use this information to calibrate laser power, and with suitable software the information can be read by users to more accurately describe aspects of the disc itself. This data may be read by ISRC and ATIP code viewers such as CD Media Code Identifier (http://www.softpedia.com/get/CD-DVD-Tools/CD-DVD-Rip-Other-Tools/CDR-Med... ). This tool allows users to view information such as dye type, disc manufacturer, capacity, write speeds and media type. Clover also provides freeware device, IRSCView (http://www.cloversystems.com/ISRCView.htm) will display the Table of Contents, Control Codes, and ISRC codes on Audio, Mixed Mode, and Enhanced CDs. It provides much less manufacturer information than the CD Media Code Identifier.

Fig 1 Section 8.1: A schematic view of a CD-R (not to scale).

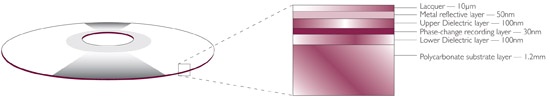

Fig 2 Section 8.1: A schematic view of a CD-RW (not to scale).

8.1.4.5 Rewritable CDs and DVDs operate on an entirely different principle. Rewritable discs are erasable and can be rewritten, albeit a finite number of times. The recordable layer is made of germanium, antimony and tellurium. A laser is used to heat the surface to two set temperatures. The higher temperature is known as the melting point (approximately 600 degrees centigrade), while the lower level temperature (approximately 350 degrees centigrade) is described as the crystallisation temperature. Heating the disc, and controlling the cooling rate, produces a track of amorphous or crystalline areas. Due to the different reflectivity these areas will be interpreted by the reading laser like the pit/land structure of a CD-ROM. Earlier rewritable discs and drives could only be written at relatively low speeds and this was encoded and implemented in the first generation of drives and standards. More recent developments have provided a mechanism for burning data onto rewritable discs at a higher speed. Though the older drives will read a new high speed rewritable disc, only the latest generation of disc burners will write a disc of the latest formulation.

8.1.4.6 No trustworthy analysis of the medium or long term reliability of RW discs has been undertaken. Preliminary investigations suggest that the film layer containing the encoded information may degrade at a quicker rate than dye based CD-Rs (Byers 2003:9), other commentators disagree. From a purely practical point of view, CD and DVD rewritable may present a greater risk if used for preservation purposes as they may be overwritten by accident with a resulting loss of the original files.