Solvent Extraction

As PE-U binders degrade, scission of ester linkages occurs by hydrolysis, the polymer chains become shorter and the binder is said to lose molecular weight. A characteristic of such lower molecular weight polymers are that they become gummy or sticky rather than retaining their strength and integrity as an elastomer. Whereas the properly cross-linked binders are largely insoluble, the lower molecular weight residue will literally wash away in solvents such as acetone and methyl ethyl keytone (MEK) (Fig.4). A technique put forward by Cuddihy 9 in 1980 was to weigh a sample of tape before soaking in solvent and dissolving out the low molecular weight binder residue, then re-weighing the sample to determine by difference (percentage w/w) the amount of broken down residue lost in the process of extraction.

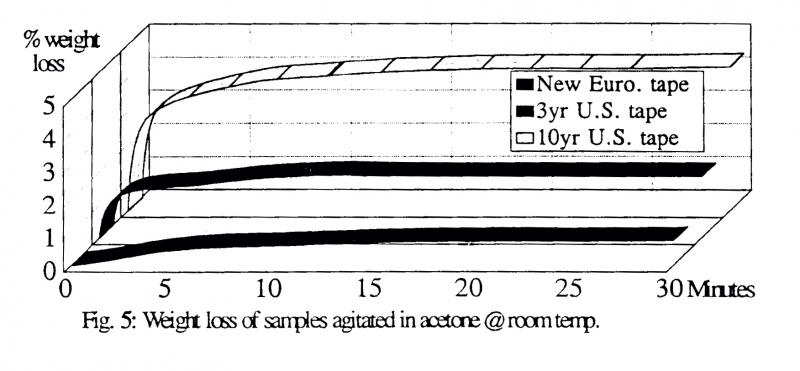

Since a PE-U tape in good condition has only a small percentage of solvent-extractable residue, typically 0.5-1%, whilst sticky unplayable tapes are often closer to 4 or 5%, it is possible to obtain a rough indication of binder condition even without a reference level for a particular formulation. Similarly an artificially aged tape showing an increase of more than a few percent extractables is inclined to instability, particularly when one accounts for the nature of additives such as plasticisers and fatty-acid lubricants. If a collection of tapes is properly monitored, with periodic measurements taken and records kept (along with control samples) from when new or prerecorded tapes first enter the Archive, a pattern of understanding may be developed which can serve as a basis for treating and dubbing material before it reaches a critical state. With experience, SE then can be correlated to playability for tapes of a given age and formulation.

Our own test method consists of weighing then immersing 50-100mm long samples in glass vials containing 20-50ml HPLC-grade acetone. After removal from the solvent and drying in air, the final weight is used to calculate percentage weight loss. Initial readings over logarithmic time intervals indicated that 20-30 minute immersion followed by 1-5 minutes drying time was sufficient to give stable, repeatable measurements (Fig.5).

Care and skill is required for solvent extractions on fragile tapes including those with PVC binders, which lose oxide and/or backcoat in the process. Techniques for filtration and evaporation can be used to avoid the apparent variation which has confused some attempts at such analysis. A team at the U.S. National Bureau of Standards produced similarly variable results by using tetrahydra furan (THF) which dissolves stable, high molecular weight polymers rather than acetone-soluble residue alone 5.