Restoration of tapes with a polyester urethane binder

RESTORATION OF TAPES WITH A POLYESTER URETHANE BINDER

Kevin Bradley

National Library of Australia, Canberra

Presented in the Technical Committee Open Session at the IASA/ASRA Conference, Canberra, 1992; originally printed in the Phonographic Bulletin, issue 61, November 1992, pages 87-93.

ISSN 0253-004X

IASA members may download a PDF version at no cost. If you are not a member, why not join IASA?

Baking tapes to reverse the symptoms of hydrolysis is the conventional approach to the problem of tape degradation., This is, however a “sledge hammer technique” which, while removing the obvious artefacts may damage the tape, and could leave hidden faults on an analogue tape. Acetone extraction, the method often used for evaluating the level of hydrolysis in a tape, is inaccurate and cannot be used in the specific case, it may also be questionable in the general. The paper examines these problems and suggests areas for further investigation.

In 1990, at the National Library of Australia, the collections were surveyed in order to quantify the number of tapes in the collection suffering from one of the syndromes that have been called hydrolysis. Though the problem of hydrolysis is in fact one that belongs to all tapes with a polyester urethane binder, some specific brands of tapes were deteriorating at a greater rate than others. The display of the symptoms of hydrolysis, that is tape squeal, sticky tapes and gummy deposits on the heads, are, for the most part, limited to one or two brands of tape.

The collection was surveyed by determining which tapes belonged to the critical problem area of type and age, assessing the number of these that exhibit these faults, and then surveying the collection for the identified tapes. Identified in the Library's collection were 1,140 original tapes suffering from the problem. Duplicates are not included in this figure. The collection is made up of original tapes (cf. Host Country Showcase, The National Library of Australia), consequently problems represent faults with unique items.

Due to a long awareness of the problem, some speculation on a suitable and cost effective solution into the problem had been going on. The most favoured option was one in which the tapes were stored at a very low humidity for a long period, hopefully allowing treatment of tapes in situ. In a simple hydrolysis reaction, basic chemistry suggests that the removal of water from the reaction would cause esterification, or the reversal of the hydrolysis reaction. It was hoped that this could be achieved by placing the tape in a suitable bag with a mechanism for removing moisture like “HC” paper, a moisture stabilising product that had come onto the market and was intended for use in exhibition cabinets.

To test the process we placed the tapes in a dry oven for 6 weeks at as near to zero humidity as possible (probably below 5% RH), and at a slightly elevated temperature of around 30°C. The tapes were from two different sources. Baking tapes at elevated temperatures seems to be fairly destructive, at least the level of damage has not been properly evaluated, so the idea of lower temperatures appealed. The existing literature suggested that such an approach should be successful.

When, some six weeks later, the tapes were removed, it was found that the process was not completely successful and a large number of the tapes were still exhibiting signs of hydrolysis. Due to the subjective nature of assessing improvement in uncalibrated, and consequently, unmeasurable audio signals, it was difficult, if not impossible, to quantify the level of amelioration. There was a feeling that some improvement could have occurred, but how could we measure this? Given the times and conditions, and based on the literature available,the treatment should have produced a complete reversal of the hydrolytic reaction. There is no agreed measurement for the level of hydrolysis and the level to which it must be restored. The only rules seem to be “if it squeals, bake it until it stops”. To further muddy the waters, it would seem that most of the papers reported tests that were carried out on artificially aged tapes, and there may be some reason to suspect that they are not wholly reliable.

This led us to investigate the four main points I want to discuss in the paper. I don't necessarily have solutions to the problems, but the questions cause us to reflect on how we treat our hydrolysed tape problem.

- Is the breakdown of tape a purely hydrolytic reaction, and does the heat treatment reverse it?

- Are artificially and naturally aged tapes the same?

- How do we measure the level of tape degradation and restoration, particularly with analogue recordings which would be affected by the problem?

- Is acetone extraction an indication of the condition of any specific tape?

Is the tape undergoing a purely hydrolytic reaction? The hydrolytic reaction is an ongoing process, the linkages in the polymers that make up a tape hinder, cleave and reform without any apparent long term loss in molecular weight and this occurs at low humidity, in other words, in well maintained storage conditions. However, if this reaction occurs in the presence of a fatty acid, then the reformed polymers may have a permanently lower molecular weight (Anglin 1991). In other words, they will produce the symptoms of hydrolysis, head clog and tape squeal.

Fatty acids are often present in tapes as lubricants and when they are involved in the reaction, the loss of the lubricant as well as the production of unwanted sticky by-products is a result. This is a dilemma for tape manufacturers, the very product that makes a tape impervious to wear, also sows the seeds for its long term destruction (Layne 1991).

Secondly, the manufacturers of the tapes that belong to the target problem period, that is those that are showing signs of hydrolysation in storage now, sourced a lot of sub-standard polymers in the production of their tape. These polymers pass through the hydrolysis and esterification reactions more readily than the longer chain polymers.

Tapes manufactured now have tighter quality control over their raw materials, and though information is scarce about precisely what is in the concoction that makes up a tape, I believe the concentration of fatty acid lubricant is less, or at least better controlled.

An artificially aged tape will not necessarily be the same as a naturally aged one. If a recent polyester urethane tape is subjected to extreme conditions to simulate age, it will not produce the same reaction as in an older tape as the make-up of the hinder is now significantly different. An artificially aged tape may produce different products to a naturally aged one quite apart from these reasons because “there is a degree of uncertainty about what is happening to the binder when tapes are aged at low relative humidity” (Brown, Lowry and Smith).

So while it is possible to reverse a hydrolytic reaction in a dry condition at room temperatures in an artificially aged tape, it is not necessarily the case that a naturally aged tape will react the same. By the same token, it may he that the partial improvement results in a playable tape, but that some of the artefacts of hydrolysation are being passed to the duplicate of the recording, due to the incomplete, though unmeasured reversal of the reaction.

Almost all the research done to date that attempts to link physical condition with playability has been done on data storage tape, most often the ½” tape used by the computer industry for information storage The reasons for the choice of data tapes is twofold Firstly it is easy to measure readability faults with a data tape, error readings can be linked to the condition of the tape simply and accurately. Secondly, funding and support for these kinds of projects come from the computer industry which has an interest in saving this data and to which monetary value can be ascribed.

Though it is possible to extrapolate from the data recording and apply the results to analogue recording, there is an element of degree that is insignificant in a digital recording, but that may be a problem in analogue recording. A data recording will stand a higher level of speed variation than analogue and show no sign of the problem. When a hydrolysed tape is copied, artefacts of the process may inadvertently be passed on. It may be that scrape flutter or other speed related problems, though low in level, is now an integral part of the duplicate.

There is reason to be concerned, or at least to investigate this problem. Commercial remastering engineers often encounter hydrolysed tapes, at least in Australia, and recover them by placing the tape in an oven at high temperature and replaying the tape the following day. This is the standard practise. Many have reported an unexpected high frequency boost, or an increase in what they term clarity. One engineer seriously suggested that he might routinely bake all the tapes he remasters, hydrolysed or not! In the National Library of Australia hydrolysed and nonhydrolysed tapes from a similar source have been compared after restoration of the degraded tape Though there was an observed difference it was not quantifiable and may have been attributed to a number of other variables.

The project aim of the Library was to investigate a way of linking chemical or physical condition of a specific tape with the analogue replay characteristics This was to be achieved by recording a series of different tones to allow the measurement of such standard things as:

- frequency response

- noise and distortion

- scrape flutter and other speed variations in limited frequency bands

- intermodulation distortion

The tape would be gradually aged and then gradually rejuvenated, and the resulting changes in properties measured. It was intended to use acetone extraction as a method of measuring the chemical degradation.

The rationale behind solvent extraction is that the polymers with a lower molecular weight are soluble in acetone and those with a higher molecular weight are not. In other words it should be possible to remove in solution the products of hydrolysis and by measuring the difference in weight between pre and post immersion in solvent deduce, the amount of polymer in the binder that has been hydrolysed.

The results, to jump ahead slightly, were unpredictable and the values shown are from the most reliable process. Prior to this, various methods of stirring the solution were tried to ensure predicability, from mechanical stirrers to soxhiet extraction. In the end, the orbital shaker, which does four beakers at once was employed to stir the solution.

A reel of blank, naturally aged tape that exhibited the characteristics of hydrolysis was cut into lengths of 200 mm, weighed and placed in beakers with 20 ml of acetone. The beakers were agitated for around 25 minutes, though, in practise, any time longer than 20 minutes and less than 50 minutes seemed to make very little difference. After this time the tapes were removed from the solution and rinsed in clean acetone to dislodge any material in solution and still attached to the tape. The tapes were then left to dry for a minimum of two hours, and then were weighed. The difference was calculated and expressed as a percentage of the total weight of the tape.

% change= Wt-Ws/Wt * 100/1

where

Wi = weight before extraction

Ws = weight after extraction

The tests were repeated a number of times and the results plotted. There was a wide variation between the results.

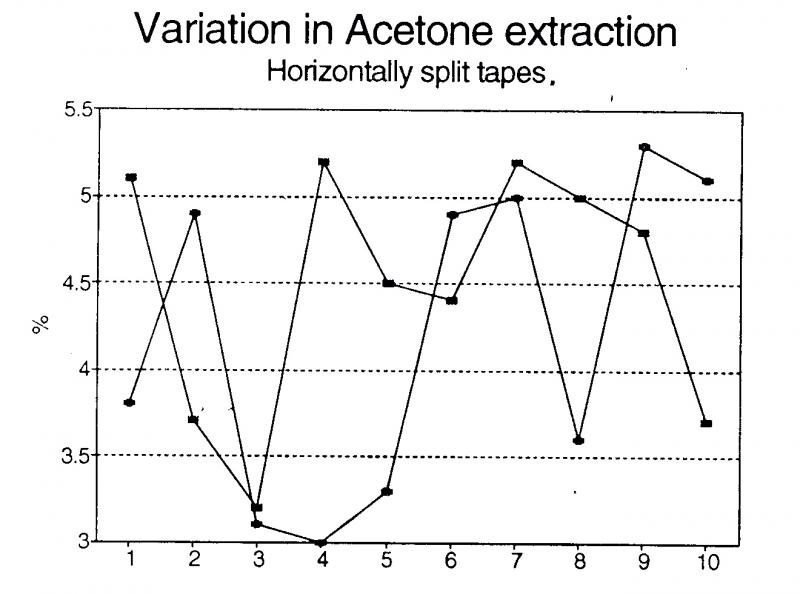

This graph shows the variation between the percentage of material extracted from pieces of tape taken consecutively from a reel. The variation is significant, nearly 50% difference can be found between the highest and lowest percentage extraction.

To reduce this variation, or at least to see if it was related to position on the reel and exposure to environmental conditions, we took the 200 mm lengths of tape and split them down the centre. The tapes were then put through the acetone extraction process and the two halves compared. The process was again repeated and the result plotted.

This graph shows the variation between the two halves of the tape, the variation is again significant.

Brown, Lowry and Smith claim that a 5% acetone extractable content would equal in weight 60-70% of the organic binder being soluble. Practically, this extrapolation is hardly likely to be accurate. When a naturally aged tape is placed in acetone to extract the soluble component of the binder, the material the binder is designed to hold is also removed with the solvent. Within a few minutes, the backcoat begins to show visible signs of disengaging itself from the tape, certainly well before any significant amount of binder has been dissolved. Oxide in small quantities also leaves the tape during the process, though this probably weighs more, it is less visually obvious. When a new or artificially aged tape is shaken in the acetone, the loss of oxide and backcoat is much less.

A 5% extraction of soluble material is in keeping with the work done by Cuddihy, who got a similar result in his tests. Our 5% extraction included a significant amount of backcoat and oxide, components which would affect the measurement of overall weight loss. It would, therefore, reflect a figure somewhat less than the 60-70% of organic binder materials suggested by Brown, Lowry and Smith.

The combined weight of oxide, backcoat and binder material amounts to around 30% of the total weight of a tape, the substrate amounts to around 70%. The 5% extraction refers to the total weight of material including the largely insoluble substrate. When the figure of 5% is compared to the possibly removable amount of material of 30% the figure derived from acetone extraction is around 17% when compared to this, the errors are also correspondingly larger. When comparing this to the total weight of organic extractable binder material, which is around 8%, the variations are even more alarming.

Under these sort of conditions, it would seem that it is not possible, using acetone extraction, to determine with any degree of precision, the condition of a given tape. And even if there was a process that would allow us to measure the degree of degradation there is no way of correlating this to performance, and no way of applying a level of restoration to the particular problem. The National Bureau of Standards report concurs, stating that the acetone extractable percentage (or sol content, as they call it) is not a good indicator of the lifetime of a tape [Brown, Lowry and Smith].

If we return to our four questions, we must conclude that there is a great degree of uncertainty in treating hydrolysed tapes and there is not a really satisfactory method of determining the condition of any particular tape, other than the purely subjective one of playing the tape.

We, as sound archivists, are faced with a dilemma: how do we treat our hydrolysed tapes? While putting them in an oven produces results, it seems that the present explanation of rejuvenation is not appropriate. We are putting our tapes in the oven of ignorance. Are we doing damage to the tapes in the process? If we wait while another solution is found will the tapes degrade beyond hope of repair? This is certainly possible with artificially aged tapes, but will natural conditions degrade a tape beyond the repairable?

I know as a preserver of sound that I am under pressure to resolve the situation and provide immediate access to the material. As a consequence, I bake a tape if there is a request to use it. Should we then just accept the problems with good grace and be grateful for the tapes that are now playable and which were not before?

I personally think we should concentrate our efforts into finding a suitable way of measuring the level of degradation of polyester urethane binders in the particular case, and to find out if degree of degradation is significant in the most important area, that is, the replay of the tape. Armed with this information we can then apply the minimum of the potentially damaging restorative work accurately, rather than the haphazard and potentially damaging way we are now.

The author would like to acknowledge the work done by Leanne Brandis, scientist and fellow member of the National Library of Australia*s Preservation Services Branch. Ms Brandis performed or set up the laboratory measurements and ensured the accurate realisation of the chemical analysis. Kevin Bradley and Leanne Brandis will be jointly working on the further recommendations in this paper.

References

- D. Anglin, Audio Mastering Archive Stability. Ampex Media Recording Corp. Paper for the Audio Engineering Society Inc. 3rd Regional Convention, Melbourne, August 1991.

- H.N. Bertram, E. Cuddihy Kinetics of the Humid Aging of Magnetic Recording Tape. IEEE Transactions on Magnetics, Vol. Mag-l8, No 5, September 1982.

- D.W. Brown, R.E. Lowry and L.E. Smith, Prediction of the Long Term Stability of Polyester Based Recording Media. US Department of Commerce, National Bureau of Standards et al.

First Annual Report June 1982

Second Annual Report August 1983

Progress Report December 1984. - E. Cuddihy Aging of Magnetic Recording Tape. IEEE Transactions on Magnetics, Vol. Mag-16, No 4, July 1980.

- F. Layne Ampex Seminar. Canberra ACT August 1991.