3.4 Mechanical deformation

Mechanical deformation is a major threat, which affects all kinds of audiovisual carriers.

3.4.1 Mechanical carriers

Fragile carriers (cylinders, shellac discs) must be given special attention when handled and transported. Extreme care should be given when mounting of cylinders on replay machines equipped with mandrels. Invisible cracks may lead to the bursting of such cylinders when mounted with too high a pressure. Additionally, keeping cylinders in mobile shelves is inadvisable. Best transport protection is achieved by tight packing within shock absorbing containers.

All mechanical carriers are prone to surface damages, which will cause audible artefacts (clicks, crackle, etc.). Additionally, the information carried by the grooves is specifically threatened by maladjusted mechanical pick-up systems and wrongly chosen styli. Both may cause considerable damage (IASA-TC 04, 5.2 and 5.3).

Because of the susceptibility of all mechanical carriers to physical damage, their handling requires staff with manual skills and special training.

3.4.2 Magnetic carriers

3.4.2.1 Magnetic tape. Mechanical integrity is a commonly underrated factor in magnetic tape preservation. In order to minimise stress, particularly with brittle CA tapes and all kinds of thin tape, tape handling must be optimised by using the latest generation of replay equipment that permits lower tape tension while still providing intimate tape-to-head contact. Such equipment will also allow fast winding at relatively slow speeds (“library wind”).

Most importantly, all open reel and cassette tapes must be stored with absolute flat winding packs only, as any stepped wind will create curled tape edges. Generally, one of the two tape edges is the reference in guiding the tape through the machine, especially with rotary head formats. Any malformed edges will result in vertical tape movement causing a variety of replay artefacts such as oscillation of stereo balance in audio or “flicker” through tracking problems in video recordings. Flat winds can best be achieved by winding the tape forward after use to its end and then back over its entire length in one continuous pass at library wind speed. Machines generally failing to achieve flat winds must be serviced or exchanged. Some tapes, however, may resist the production of a flat wind even with the use of a library wind option. In these cases, the tape should be played at a high replay speed to achieve a flat wind for storage.

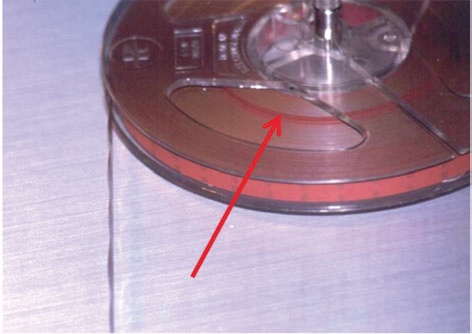

Figure 21: Tape rewound before its end. The step left in the wind will cause a deformation in this area. For flat tape winds, tapes and cassettes have to be rewound over their entire length.

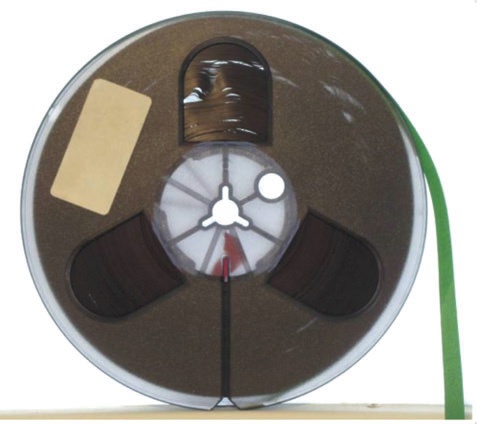

Figure 22: Uneven tape wind causing tape edge deformation.

Figure 23: “Windowing“. Manual intervention may be needed to get a flat wind without damaging the tape through friction by slipping tape.

Flanges of plastic and metal reels must be absolutely flat to avoid touching the tape during replay and specifically in the fast wind mode. Additionally, tape guides must be adjusted to ensure tape packs are formed in the middle of hubs, avoiding squeezing tape towards one of the flanges. Slots in the hubs to take up leader tapes have often led to a permanent deformation of several winds of tapes after many years of storage. Misshapen reels must be replaced, preferably by ones with slot-less hubs. Permanent slot marks can also be removed by a slightly different placement of the leader tape into the slot. Regular repositioning, however, would be needed to avoid new deformations.

The use of flangeless hubs originated with the original German “Magnetophon” of the 1930s and was maintained for studio and radio applications in continental and Eastern Europe thereafter. Its application requires back-matted tapes, machines with adequate tape tension control in all operating modes, and, above all, careful and skilled handling. Such freely wound tapes are stored on their hubs, hanging on a suitable suspension in the centre of the box. It may happen, however, that the tape pack falls apart, due to pressure on the hub, or a loose wind (see figure 11). Restoration of the tape wind calls for manual skill and patience. Special devices, known as “Wickelretter”, which have hinged, sectional hubs that can be moved inwards to fit inside the pack and then moved outwards again to hold the tape pack while slowly rewinding the tape on to a new spool.

Figure 24: “Wickelretter” - device to assist the rescue of tape packs if hubs had slipped out.

Once CA tapes become brittle, they often have a tendency to “escape” from a flat pack during fast wind. It is, therefore, a wise precaution to wind them onto spools.

With cassette tapes, the loading and unloading procedure constitutes a significant stress to the tape resulting in measurable drops-outs after several tens of such actions. Also, malfunctioning mechanisms may jam and damage, if not destroy, the tape. Consequently, cassettes must only be loaded and unloaded at the unrecorded portions at the beginning or at the end of tape. If this is done, tapes that get jammed can be repaired by cutting off the damaged part without loss of recorded material. Therefore, when recording a programme on a cassette, sufficient room should be left blank as a loading area at the beginning and the end.

Regular cleaning of tape guides and heads—at least daily—must be performed using tools soft enough to avoid damage to heads and guides. Such damage will scratch tape surfaces, which endangers its chemical stability (2.2.1.1.3).

3.4.2.2 Hard disk drives. Generally, because of their moving parts, hard disk drives should not be exposed to mechanical shocks. Moreover, it must be noted that shock damage is more likely under operating than in non-operating conditions, when the read head is safely parked away from the hard disc surface. Hard disk recorders must always be handled with great care, particularly during recording and play back.

3.4.3 Optical discs

Optical discs must be kept free of mechanical damage and scratches. Scratches on the read-out surface will obstruct and/or divert the laser beam, while a damaged protective layer on CDs and BDs will endanger the chemical integrity of the reflective layer. Writing on protective layers (label side) can only be done on recordable discs and then only by using special CD felt pens. Ordinary felt pens must not be used as their solvents may dissolve the protective lacquer. Writing with hard tipped pencils or ballpoint writers may mechanically disturb retrievability. Bending of optical discs must be avoided, as this may crack the reflective layer. Consequently, when releasing optical discs from the centre holding clamp, two hands should be used — one to release the holding mechanism and the other to remove the disc.

3.4.4 Solid state carriers

Daily experience with solid-state data carriers suggests a level of robustness against some shocks, e.g. when dropped on the floor. It should be borne in mind, however, that due to their microscopic structure, some mechanical stresses, e.g. bending memory sticks in pockets, may lead to their immediate destruction.