2.2.1.1 Magnetic tapes

In its present form magnetic tape recording was developed in the 1930s by AEG Telefunken and introduced for professional application in 1936. It became widely used within the German Radio. Because of World War II, however, its use was restricted to Germany. After the war it came to the United States from where it spread worldwide. In the late 1940s and early 1950s the use of this recording technology was concentrated mainly in the broadcast and recording industries. From the early 1950s onward, however, home audio recorders were developed which operated at slower speeds and employed half and quarter track formats to reduce the costs of magnetic tape. However, this was at the expense of recording quality. Also, during the 1950s, transistorised portable recording equipment became available that made sound recording possible everywhere in the world. This lead to a mushrooming of recorded sound collections, particularly in the fields of cultural, linguistic, anthropological, and ethno-musicological documentation. In the 1960s, cassette formats were developed. Of these, the compact cassette soon became the dominant format in the market, and is still in use.

In addition to magnetic tape, magnetic wire recorders were developed in the United States in the 1940s. They also gained some popularity in Europe in the 1950s and 60s.

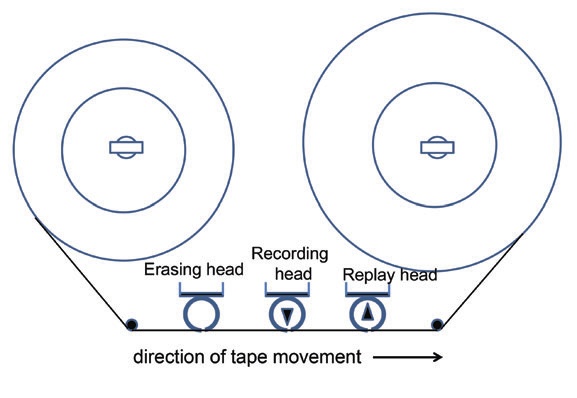

Figure 7: Principle of magnetic audio tape recording. In such “linear“ recording, the speed of writing is the same as the speed of the tape.

After several experiments, digital audio recording on magnetic tape was introduced in the 1980s. All of these early professional and semi-professional formats are now obsolete. In 1987 R-DAT (Rotary head Digital Audio Tape), a digital recording cassette format, was marketed and gained some popularity in semi-professional and professional circles. Since about 2005, however, it has also become obsolete. Now all audio specific magnetic tape formats are, in practice, dead. Audio recording, post production, and storage have become part of the IT (computer) world with its specific carriers and formats.

From 1956 onward, magnetic tape was also used for video recording. Several professional reel-to-reel formats were developed and in use until the late 1970s. They were followed by professional analogue and digital cassette formats. For home recording, early open reel formats were available from around 1970 and, around 1980, cassette home formats became widespread. Of these, the VHS format survived until recently. For small handheld camcorders (“handy cams”), an 8 mm cassette system became popular (Video8, VideoHi8), which was still in use in the early 2000s. Digital home formats were introduced in 1996. The Mini DV format dominated handheld camcorders from the early 2000s but has also become obsolete, replaced by optical, hard disc, and solid state (“flash card”) recording systems. The same development for the last remaining professional video tape formats is under way.

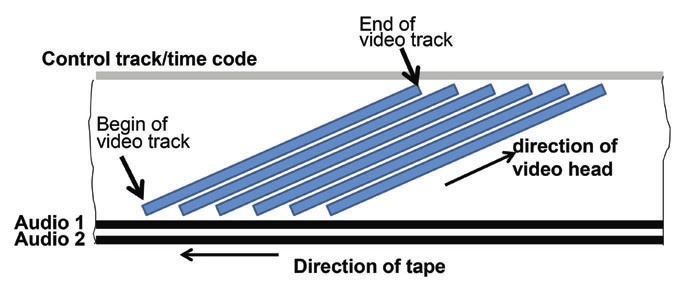

Figure 8: Principle of magnetic video recording. The high bandwidths of video signals require high recording speeds, which are achieved by a fast rotating head that writes narrow video tracks across a tape moving at a much slower linear speed. This principle of “helical scan” recording is also used for digital video formats and R-DAT.

Thus, video has developed in a similar way to that taken by audio. Proprietary video-specific formats are being replaced by file formats. Recording, postproduction and storage have, like audio, become part of the IT world.

Some video cassette formats have also been used for audio only recording purposes (IASATC 04, 5.5.7).

Beyond specific audio and video formats, magnetic media are the most prominent storage media in the IT world. Magnetic tape plays an important role as a computer backup medium and hard disc drives (HDD) have seen tremendous growth both in professional and home applications. Both carrier types have become the backbone of professional digital audio and video archiving. While this publication concentrates on (traditional) audio and video tapes, the basic principles described are valid for magnetic computer media.

2.2.1.1.1 Components of magnetic tapes and their stability

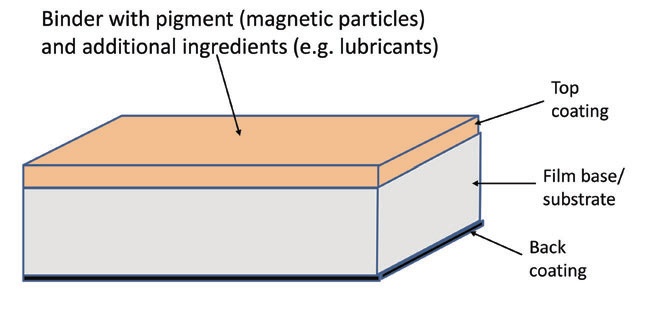

Magnetic tape is composed of two main layers: the base film and the magnetic layer. Additionally, many tapes are back matted for improved winding properties, and to reduce electrostatic charges.

Figure 9: Layers of magnetic tape.

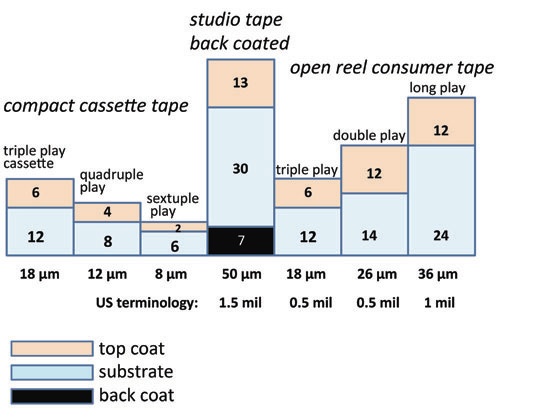

Figure 10: Cross sections of different audio magnetic tapes. Back coating may also be found on LP and DP tapes. (Friedrich Engel)

2.2.1.1.1.1 Base film materials. As magnetic tapes were developed, the following materials were used: paper, cellulose acetate (CA), polyvinyl chloride (PVC), polyester (polyethylene terephthalate, PET or PE), as well as polyethylene naphthalate (PEN).

Cellulose acetate was used from the mid-1930s until it faded out during the early 1970s. Such tapes can be identified by holding the tape pack against a light source: with some exceptions, it is translucent.

There are two processes of CA deterioration. One is hydrolysis, widely known and well researched in film preservation as “vinegar syndrome” (3.1.1.1). The other deterioration process is plasticiser loss: affected tapes become brittle.

CA audio tapes, in general, are much less affected by these deterioration processes than CA films. Specifically the vinegar syndrome seems to some extent to be a critical mass problem, which is less effective with audio tape. While hydrolysis is clearly related to high levels of relative humidity, which calls for low humidity storage, earlier literature (e.g. FIAF, 1.3, 11.2.4, 11.2.11.3) had recommended medium RH levels to prevent plasticiser loss. This is not confirmed by more recent literature.

CA audio tapes often also suffer from various geometrical deformations. As an intimate tapeto head contact is the basic requirement for optimal signal extraction, such deformations mean that the required contact cannot be achieved. Higher tape tension to improve tapeto- head contact is generally not applicable, as the tapes break because of their brittleness.7

It should be noted that severe cases of both kinds of deterioration—hydrolysis and embrittlement— mainly occur with German tapes from the early 1940s, and, more widespread, with tapes from East Germany and from the Soviet Union, produced well into the 1960s.

Figures 11 and 12: Typical brittle cellulose acetate tape before and after reconditioning (rewound on spool). The slipped tape pack can be rescued with the help of a “Wickelretter” (see 3.4.2.1 and figure 24).

Several other CA tapes are also affected. It should be noted, however, that some CA tapes from other production sources are still in good, flexible, and playable condition.

A comforting side effect of CA tapes is that they break without stretching (as opposed to PET, see below). This usually allows broken tapes to be spliced without the loss of recorded signals.

PVC tapes were mainly produced in Germany between 1944 and 1972 and as yet have not suffered from any systematic chemical deterioration. As plasticiser loss has not yet been experienced, tapes have maintained their flexibility. Due to their electrostatic behaviour, however, their winding properties are sub-optimal.

As practically all PVC tapes were produced in Germany, identification of professional tapes is easy because of the imprint on the back. Consumer tapes can be identified by the imprint on their leader tapes if the original ones have survived. Significant for all PVC tapes is their soft plasticity, which is a most welcome advantage when they are compared with CA tapes of similar vintage.

Apart from the early experiments in magnetic recording in Germany in the 1930s and occasional use after WW II, only a few paper based tapes were manufactured in the late 1940s in the U.S.

PET has gradually replaced CA and PVC tapes from the late 1950s onward. Since then, it has been used for all kind of magnetic tapes. It is mechanically fairly robust, and no systematic chemical deterioration of PET based films has been observed so far.8 However, unlike CA tape, PET elongates (stretches or “shoelaces”) before breaking, which leads to stretched tapes and unrecoverable signals. This calls for high precision replay machines and correctly adjusted tape winding, particularly when thin tapes are to be replayed.

Film base thicknesses vary between 30 µm for standard play audio tape down to 6 µm for thin audio and video cassette tapes. The thinnest CA and PVC bases produced are double play open reel tape (15 µm thickness), while thinner bases are possible with PET and PEN. PEN is used for thin digital video and computer back-up tapes.

In order to achieve stable bonding with pigment layers as well as back coating, base films are covered with thin layers (fractions of µm) of primers which are applied by the base film manufacturer or during the application of the magnetic layer.

2.2.1.1.1.2 Magnetic pigments. The very first magnetic pigment used in the 1930s was carbonyl iron. This was soon replaced, however, by a ferrous oxide (γFe2O3), which has been used for all open reel magnetic audio tape, compact cassettes of type IEC I, and the first video format (2 inch Quadruplex). γFe2O3 is brown rust and chemically stable. Because of the size of its elementary magnets, however, its capability to record the increased data density required by reducing recording speeds and tape widths was limited. In order to allow the development of smaller tapes still capable to handle the bandwidth of video signals, chromium dioxide (CrO2) was employed from the early 1970s. This permitted higher data densities, slower recording speeds and narrower tapes. Chromium dioxide and its substitutes (cobalt-doped Fe3O4) are dark grey in colour and have mainly been used for analogue video recording and for compact cassettes type IEC II. No critical observations have been made of chemical instability so far. From the mid-1970s, double layer cassette tape was produced: an iron oxide layer was covered by a thin layer of CrO2. Standardised as type IEC III, these cassette tapes gave improved signal-to-noise (S/N) ratios.

The latest magnetic pigment is made from pure iron particles (MP). It is used for digital video formats, R-DAT, and compact cassettes type IEC IV. Because of its chemical nature it is potentially prone to oxidation. After problems with early tapes in this respect, methods were developed that have prevented any widespread oxidation so far. However, in the midto long-term, MP tapes as well as ME tapes (tapes with a magnetic layer produced by evaporation under high vacuum) must be considered potentially endangered. MP tapes have a colour similar to chromium tapes with, however, a “metallic” reflectivity of their surfaces.

2.2.1.1.1.2.1 Stability of magnetic information. A constituent factor of magnetic information stability is the coercivity9 of a magnetic material. In the course of their development, magnetic pigments with ever-higher coercivity have been employed. The coercivity of carbonyl iron measures around 150 Oersted; average γFe2O3 tapes are between 300 and 400 Oe; CrO2tapes are typically 600-700 Oe; and MP and ME tape up to 1500 Oe. For data recording tape the coercivity can be above 2500 Oe.10

Apart from external fields, temperatures beyond the Curie point (3.2.1.5) and magnetostrictive action can destabilise magnetic orientation.

Magnetostriction is the disorientation of magnetic alignment by mechanical impacts. Except for very early Fe3O4 tapes, however, this effect is insignificant. Magnetostriction is positively employed for the erasure of unwanted print through signals on magnetic tape (IASA-TC 04, 5.4.13).

Contrary to widespread fears, magnetic information does not vanish with time. Properly produced, stored, and handled magnetic tapes will not lose their magnetic properties within historically relevant periods.

2.2.1.1.1.3 Pigment binders. Magnetic pigments are powders that need to be bonded together and onto the tape. In early tape production cellulose acetate was used, followed by copolymers of polyurethanes. Old CA binders are responsible for dry pigment shedding and are, therefore, regarded as a risk, as are CA tapes in general. In general, the bulk of the late 1950s and 1960s tapes have not shown severe binder deterioration problems.

Tapes from the 1970s and 1980s, however, frequently suffer from unstable pigment layers. This manifests itself as the shedding of the pigment layer in a sticky deposit—generally known as sticky tape or sticky shed syndrome (2.2.1.1.2).

2.2.1.1.1.4 Lubricants. Magnetic coatings also contain lubricants, generally fatty acids and esters, to minimise friction between the tape and the heads. The coating acts like a sponge that delivers lubricant through pores. The quantity of lubricant is greater for video than for audio because of the higher writing and reading speeds. The pores and, therefore, an adequate lubricant delivery, are determined by the calendering process in manufacture. Some lubricants have a tendency to exudate and crystallise on the tape surface, particularly stearic acid at temperatures below 8°C. This causes clogging of replay heads. Surplus lubricant can be removed mechanically, helped by elevated temperatures. Re-lubrication, as mentioned on several websites and publications, must be seen very critically, as it is impossible to restrict added lubricants to the small amounts actually needed. Superfluous lubricants are difficult to remove from tape guides, heads, and capstan and may interact with other tapes played on those machines at a later date (Schüller 2014).

2.2.1.1.1.5 Back matting originated in Germany to improve safe tape handling with flangeless hubs in radio studios. Back matting ensured a tight and safe tape pack without the risk of slipping apart. From the 1970s onward, back matting became more widely applied for audio and video tapes, generally by adding carbon black to improve conductivity to remove electrostatic charges which, together with the slight surface roughness, improves winding properties.

7. Several authors, however, report that the replay of brittle tape can be improved if stored for a period under high humidity conditions: vapour temporarily replaces the lost plasticiser. Recently, processes have been developed to make brittle tapes playable, refreshing the elasticity permanently by substitution of a plasticiser (Oesterreichische Akademie der Wissenschaften 2012, Wallaszkovits et al. 2014).

8. A theoretical breakdown scenario discussed in the 1990s did in practical use not materialise.

9. Coercivity is the property of a given magnetic pigment to resist changes in magnetic orientation or re-orientation (= "erasure"). It is defined by the level of the magnetic field needed for (re-)orientation, expressed in Oersted (Oe). The higher the coercivity, the higher the resistance of magnetic information to re-orientation (or erasure) by external magnetic fields.

10. In analogue audio recording these different coercivity values have been the major reason for the need to adjust the bias for each tape type.

2.2.1.1.2 The so-called Sticky Tape or Sticky Shed Syndrome (SSS)

From the mid-1970s onward, sticky tapes and pigment shedding have been frequently observed. These tapes often squeal during replay due to friction because of sticky pigment and binder particles deposited on tape guides and audio and video heads. This clogs the heads and leads to a significant loss of high frequencies (audio), or a complete breakdown of the signal (video).

Hydrolysis of pigment binders has been the most frequent explanation for these problems. Because this kind of hydrolysis is reversible to some degree, such tapes generally can be reconditioned for replay by exposing them to low humidity and elevated temperatures (or a combination thereof: for details see IASA-TC04, 5.4.3.4).

Recent research11, however, reveals that there are several additional possible reasons for the stickiness of tapes: primer exudation, surplus of dispersion agents, lubricant exudation, and, finally, uneven dispersion of hardener. Except for the latter, which is incurable, treatment similar to that of binder hydrolysis can be used: elevated temperature12 coupled with mechanical cleaning. This will help make tapes reproducible during a time window that is long enough to permit the transfer of their contents.

11. Schüller 2014.

12. Temperatures employed in such processes have varied between 60°C (for audio only) and 40°C. As elevated temperatures may mechanically distort tapes, which is specifically critical for video tapes, and may also have a negative influence on the further life of the tape, present thinking suggests to use the lowest possible temperature which is still effective.

2.2.1.1.3 Production process and individual integrity of a given tape as stability factors

Production process and individual integrity of a given tape as stability factors. While the chemical composition is an indispensable basis, the production process is regarded to be of even higher importance for tape stability: coating speed, proper dispersion of components, temperature and pressure of calenders are only some of the factors determining the stability of pigment layers. This may lead to a different performance between batches of the same type of tape, sometimes even with the same batch.

Additionally, the physical integrity of the tape surface plays an important role. Poorly serviced replay equipment can scratch the tape surface and create ports of entries for destabilising agents, such as humidity.

Chemical analyses are, therefore, of limited value in evaluating the quality and predicting the further life expectancy of tapes. Moreover: as the composition and production of tapes vary greatly, research results and recommendations valid for one type, or even only for a particular batch of tape cannot necessarily be extrapolated to others, let alone all tapes. In this respect generalising statements and/or recommendations by publications based on a limited number of normally not even identified sample tapes, should be regarded critically (Schüller 2014).

Figure 13: Pigment shedding: Chemical deterioration or poor manufacture?

Figure 14: Rare case of total loss of pigment. This is most likely a production problem.

2.2.1.1.4 Deterioration by replay

Unlike mechanical carriers, fairly modern and well preserved magnetic tape can be replayed several hundred times without any measurable loss of quality. However, a pre-condition is well maintained replay equipment of the latest generation, which allows gentle handling of the carriers. Older or poorly serviced machines may severely damage, if not destroy, a tape during replay.

2.2.1.1.4.1 Alignment and maintenance of equipment (replay only). Magnetic tape players need careful alignment of the following parameters:

- vertical position, azimuth, and wrapping angle of replay head (Whenever head adjustment has to be changed to compensate for errors of the recording head of a given recording, it is imperative that the heads be re-aligned to their correct settings immediately after the playback is completed.);

- vertical position of tape guides to ensure horizontal tape travel and to avoid asymmetrical position of tape packs on reels and open hubs;

- calibration of tape tension in the play and winding modes, particularly if thin (amateur) and brittle cellulose acetate tape is to be played;

- alignment of the replay amplifier according to speed and equalisation standard (Alignment is head-dependent, therefore changing head blocks for different track formats will require re-alignment of the replay amplifier, or amplifiers switchable to different pre-settings.).

Maintenance comprises:

- the cleaning of tape heads and tape path (Frequency of cleaning is dependent on the abrasiveness of tapes in use. All surfaces of the tape path must be kept in perfect condition in order to avoid any scratching of the tape surface (2.2.1.1.3) as well as to avoid irregular speed fluctuations and to guarantee smooth tape-head contact.);

- frequent (daily) demagnetising of tape heads and tape guides (3.7.2.1.1);

- complete check of alignment and recalibration every 50-100 hours playing (not running) time.

The keeping of logbooks for each piece of equipment and the careful documentation of all alignment and maintenance work is imperative (IASA-TC 04, 5.4.)

2.2.1.1.5 Strategy for the access to magnetic tape collections

Although, in contrast to mechanical carriers, magnetic tapes can be replayed several hundred times without measurable deterioration of the recording, provided modern and well maintained equipment is employed, there is a statistical risk of damage to tapes through unforeseen malfunction of replay equipment. In particular, thin (LP, DP and TP) open reel tape and all cassette formats are prone to such rare, but unpredictable threats. In the analogue era this has led to a strategy of copying vulnerable original tapes to sturdy studio tapes and to making listening copies for recordings in frequent demand. Whether digital repositories are already in place or not, this strategy is still valid in the digital era, as most original digital audio and video recordings are extremely vulnerable. CDs and DVDs have proved ideal media for access copies (but not for master or preservation copies). As with collections of mechanical carriers, a request for access is often a trigger to prioritise the digitisation of that material.