2.3 Optical carriers

Optical carriers are the oldest audiovisual carriers. They have been in use for analogue image representation for more than 170 years. For the storage of audio and video signals, however, they are amongst the youngest group of carriers. Although optical tape formats have been developed, they have not reached market acceptance. Therefore, optical audio and video carriers are restricted to disc13 formats.

13. Spelling of disc vs. disk; this publication joins the orthography of IASA-TC 04, second edition: all analogue and optical discs are spelled discs; magnetic disks are spelled disk.

2.3.1 Recording principle

This is different to photographic carriers, which work by absorbing varying amounts of light. Optical discs rely on the creation of tracks of microscopic size that change the reflection of a laser beam, thus permitting the retrieval of the recorded signal.

The ancestor of optical discs was the Laser Vision Disc, which was developed for analogue video signals in the late 1970s. The technology and format parameters, but not the size, were taken over by the Compact Disc which was marketed as a replicated or pressed digital audio format in 1982 (CD-A, defined as Red book standard). It was soon discovered that, beyond audio, CDs would also be an ideal medium for the dissemination of general data, such as text, graphics and moving pictures, which in 1985 gave birth to the replicated data CD (CD-ROM14, Yellow book standard). In 1987 the interactive CD (CD-I, Green book) followed. By 1991 recordable CDs (CD-Rs, Orange book standard) and rewritable CDs (CD-RW, also Orange book standard) were developed. Finally, in 1993 a video CD standard (CD-V or VCD, White book standard) was defined, which has gained great popularity in East Asia.

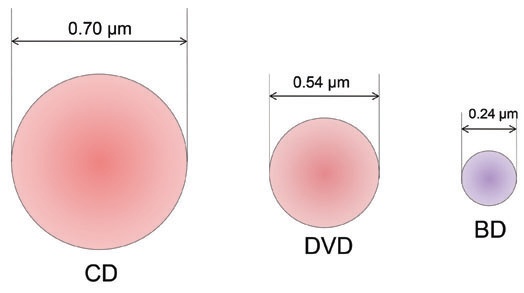

In order to increase the capacity of optical discs, mainly to make them suitable for the storage of video films, the DVD (Digital Versatile or Video Disc) was introduced from 1995 onwards using the same recording principles as CDs. By reducing the laser wavelengths and thus reducing the track dimensions, the storage capacity was increased by a factor of 7 for each DVD layer. By 2005/2006, storage capacity was increased again to make optical discs capable of storing HDTV signals. Of the two competing formats, the HD DVD and the Blu-ray Disc (BD), the Blu-ray ultimately succeeded, while HD DVD was suspended. Blu-ray makes use of short wave lasers (“blue-violet laser”) which permits a further step in the miniaturization of signal representation and thereby an increase in data density.

Finally, magneto-optical discs (MOD) should be mentioned in this context. Originally used in the computer world for storing data, they have lost their earlier importance with the dramatic increase of storage capacity of hard disc drives (HDD) at ever lower prices. In the consumer world they have gained some popularity, however, in form of the (rewritable) MiniDisc (MD).

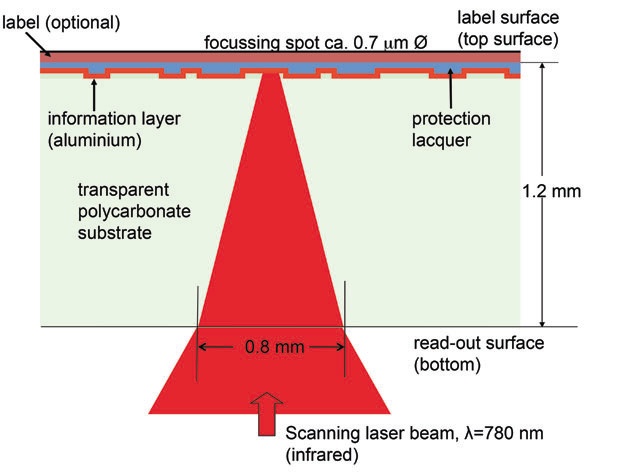

2.3.1.1 Replicated CDs, DVDs and BDs (-ROMs). These discs consist of a transparent body of polycarbonate, 1.2 mm in thickness, replicated by injection moulding using a negative metal “stamper”. The upper surface of this body carries a spiral track of “pits” (holes) and “lands” (flat areas) of varying lengths. The “pitted” surface is covered by a reflective layer of aluminium, which is covered by a protective lacquer. This surface also carries the content /label information. A laser “reads” the information from underneath: It is focused so that it hits the pits and lands that form the track. The depth of the pits is ¼ of the laser wavelength, which gives a change in the reflection of the laser beam at the transition between pits and lands. Such changes represent digital 1’s while no change represents 0’s.

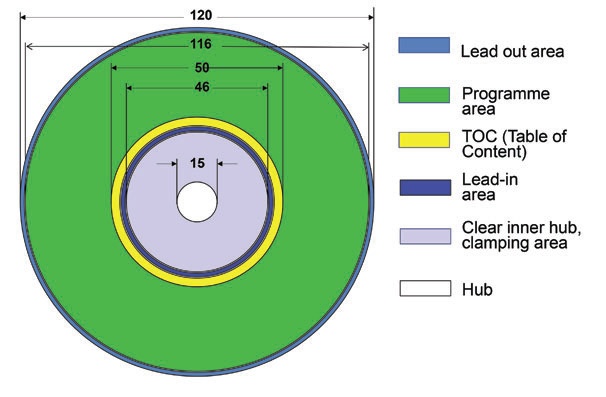

Figure 15: The partition of a CD-ROM; figures in mm.

Figure 16: Layer structure and reading principle of a CD-ROM.

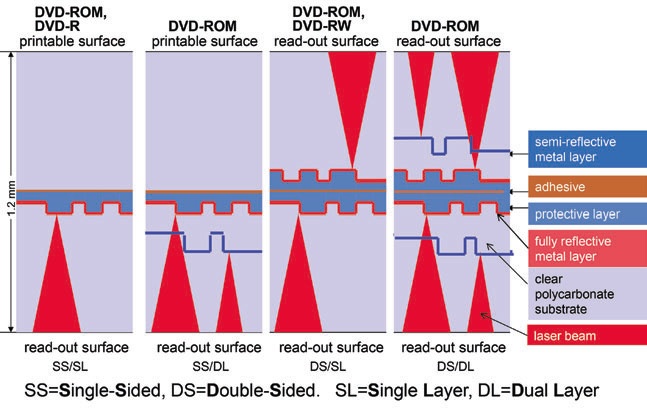

DVDs have narrower tracks and shorter pit/land lengths than CDs: they use a shorter wavelength laser. The basic disc is only 0.6 mm thick. With single sided DVDs, a blank second carbonate layer is bonded to the information carrying half. With double sided discs, a second information-carrying half is attached. Additionally, it is possible to add a second, semi-transparent layer (dual layer) to each data layer. This makes two layers readable from each side, almost quadrupling the storage capacity.

Figure 17: Layer structures of DVDs

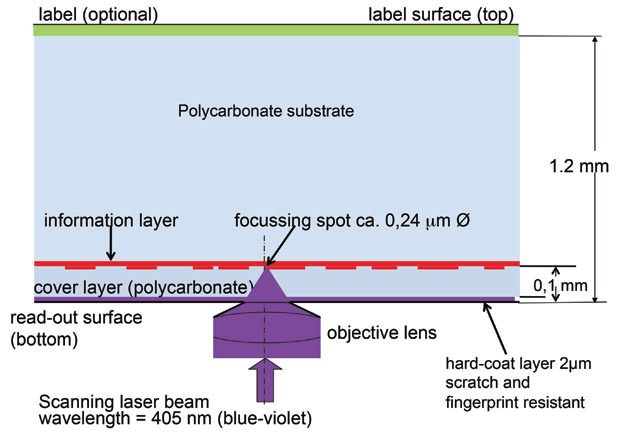

Replicated Blu-ray discs (BDs) consist of two laminated polycarbonate bodies of different thicknesses. The lower, thinner one carries the pit-land track on its upper side covered by the reflective layer. The track is narrower than that of a DVD or CD. The upper, thicker polycarbonate body carries the label on its upper surface. Unlike DVDs, there are no double sided discs, but dual layer BDs are available.

Figure 18: Layer structure of the Blu-ray disc.

Figure 19: Focusing spots of CD, DVD, and BD.

2.3.1.2 Recordable optical discs (“Dye Discs”, CD-Rs, DVD-Rs, BD-Rs). The information layer consists of a groove in the upper surface of the polycarbonate body filled with an organic dye. Recording is made by a laser of much higher energy than the reading laser, which heats (“burns”) the dye. By this process, a sequence of burned and non-burned spots are created. The transitions between burnt and un-burnt areas are recognized by the reading laser in the same way as the pits and lands of replicated ROM-discs. Reflecting layers are of gold, silver, or silver alloy.

Figure 20: Injection moulded pits and lands (left) vs their burnt equivalents (centre and right) in CD-Rs (Jean-Marc Fontaine).

2.3.1.3 Rewritable optical discs (CD-RWs, DVD-RWs, BD-RWs). The information layer consists of a phase-changing metal alloy. Recording is made by a writing laser that heats up the metal alloy film at the exposed spot, inducing a phase change from crystalline to amorphous and vice versa, controlled by the burning temperature of the writing laser. Dielectric layers on both sides of the metal alloy film cause rapid cooling; the heated spots keep the changed phase after cooling. The amorphous film spots reflect the light of a reading laser with lower intensity than the crystalline areas allowing the transition between states to be recognised. Data can be erased and rewritten for a limited number of times (up to 1000 times).

2.3.1.4 Magneto-optical discs (MODs). The information layer is magnetic while the recording and reading process is optical. The recording is achieved by heating the magnetic information layer with a laser beam beyond its Curie point (3.2.1.5), which allows magnetic (re-)orientation by applying a very low magnetic field. The replay process makes use of the Kerr effect (see also 2.2.1), by which the magnetic orientation of the information layer causes different angle reflections of the reading laser. Actually magnetic carriers, for handling and storage purposes magneto-optical discs are grouped with optical discs proper, as their architecture is very similar.

Magneto-optical discs (more frequently spelled disks) were in professional use as a data back-up and transport medium in the 1990s. They came in different sizes (90 and 130 mm) and different storage capacities, and were housed in cartridges for protection against mechanical damage and foreign matter. With the development of hard disk drives (HDDs, 2.2.2) and their increasing storage capacities at ever-lower prices, magneto-optical discs have lost their importance.

2.3.1.5 MiniDisc (MD). The MiniDisc was introduced in 1992 as a replacement for the analogue compact cassette. It was popular for consumer use for over a decade, until its use faded in the later 2000s. It comes in two versions: as a magneto-optical disc (2.3.1.4) for recording purposes and as a replicated disc for pre-recorded content, which technically is like a CD-ROM. MiniDiscs are 2.5 inch (64 mm) in diameter and are housed in a cartridge, which makes them relatively resistant against mechanical damage and foreign matter. For their replay see IASA-TC 04, 5.6.10.

14. For the terminology of the classification of optical discs, this publication follows the recent development: originally replicated discs used for general data were called CD-ROMs (ROM=Read Only Memory). With the advent of recordable/rewritable CDs, this terminology became inconsistent. Recent publications on optical discs divide them into -ROM (replicated), -R (recordable), and -RW or -RAM (rewritable). All three types may contain audio, video, or general data.

2.3.2 The components of optical discs and their stability

The polycarbonate used for optical disc bodies is a transparent polymer with a low thermal expansion factor. It is resistant against deformation by heat at temperatures of up to 130°C. Early discs, especially LV discs, sometime had problems with crazing which made the polymer opaque and unreadable. From experience gained since the introduction of CDs in 1982, it can be expected that modern polycarbonate discs will be stable for several decades.

Apart from gold, all of the metals used to provide the reflective layers are prone to oxidation. Therefore, the protective lacquer layer of CDs plays an important role. It must be resistant against penetration of humidity, a function that often did not work properly with early CDs. Oxidised reflective layers, particularly aluminium, render optical discs unreadable.

The stability of the adhesive that keeps the two polycarbonate parts of a DVD or a BD together is unknown.

The stability of the dyes used in recordable CDs, DVDs and BDs is a factor of great uncertainty. There are three different dyes in use: cyanine, phthalo-cyanine, and azo. All dyes are susceptible to light, specifically uv radiation: an exposure of recordable discs to daylight will render them unreadable within a few weeks. Another uncertainty factor is the decrease in the amount of dye used for discs designed to run at higher recording speeds.

The life expectancy of dyes is often quoted to be between 5 and 100 years, an item of information that is of little practical use. The stability of the semi-transparent layers of DVDRs and BDs is unknown. Finally, the stability of rewritable discs is also unknown, and their potential life expectancy as compared to dye discs is unclear.

2.3.3 Deterioration by replay

There is no (measurable) deterioration by replay with optical discs.

2.3.4 Alignment and maintenance of equipment

Optical disc readers are non-adjustable mass-produced products, which is part of the problem explained below (2.3.5). Maintenance is restricted to occasional cleaning of the lens with the help of a cleaning disc, and of the loading tray.

2.3.5 Recording quality as a constitutive factor of life expectancy of recordable optical discs

Recordable optical discs (CD-Rs, DVD-Rs, BD-Rs) have become very popular media for audio, video, and data recording. As with many other digital carriers, their reliability depends on a sophisticated error correction system that permits the full reconstruction of the information even if small parts of the medium have become unreadable because of damage or deterioration by ageing. The correction capability is limited and, therefore, the quality of the recording becomes an important factor of life expectancy. A perfect, almost error free recording leaves more correction capacity to compensate for handling and ageing effects and, therefore, enhances the life expectancy. If, however, optical discs start their life with a high error rate, then there is little capacity left to compensate for further errors. The life of such discs will be shorter. Consequently, IASA has defined recommendations for maximal acceptable errors for optical discs in order to maximize their life expectancy, whatever it may be (IASA-TC 04, 8.1.9).

A major problem in burning recordable optical discs is the interaction between blanks (unrecorded discs) and writers. There are no standards defined, and the processes of automated adjustment do not always work sufficiently well. Tests have shown that randomly chosen blank/writer combinations produce 50% acceptable, and 50% unfavourable results. Consequently, to reliably burn recordable optical discs would need extensive testing of writer/blank combinations, control of each single disc produced, and further checking at regular intervals. As testing is labour intensive and test equipment is expensive, more reliable and, ultimately, more cost effective storage systems than recordable optical discs are used for professional data storage.15

15. J.-M. Fontaine, 2000.

2.3.6 Formats and sizes

Analogue Laser Vision Discs were manufactured in 300 and 200 mm sizes, mainly double sided, i.e., two discs bonded together back-to back. For the digital disc family, diameters are 120 mm for all types of discs apart from some CDs and BDs which are available in 80 mm diameter.