4 Storage Facilities and Transport

4.1 Storage environments

The control of the environment in a storage area is a product of the prevailing conditions in the surrounding area, the construction of the storage facility, the quality of insulation and vapour seal, and the air-conditioning plant; when designing a storage environment all four of these must be taken into account. Overdesigning the air-conditioning plant to compensate for poor insulation, for example, leads to unstable and variable conditions. As has been discussed earlier in this publication, stability is more important than the absolute conditions being met. The following provides some general information that can be used in discussion with the appropriate design specialist.

4.2 Storage area location

Ideally, a storage area should be in the centre of a building, slightly elevated from the ground floor. Such a location would permit effective and autonomous control over all environmental factors, including temperature, humidity and water, dust and pollution, light, as well as stray magnetic fields. Any location at the fringe of a building would make such control more difficult, and possibly less effective. Any location lower than ground level makes air conditioning more expensive, and effective prevention of water influx difficult. Vaults should be fireproof, thermally insulated, and also protected against water influx, which may happen for a number of reasons.

4.3 Air conditioning and environmental control

Air conditioning, environmental control, or building management technology are all terms used to describe systems of varying sophistication that control and manage the environment inside a building. Though such systems were developed principally for the comfort of the occupants of buildings, they are a necessity if the rooms are to meet the long-term storage conditions of the audiovisual collections as specified in this publication. In principle, air conditioning systems are the same whether they are used for preservation and storage or comfort purposes. However, air conditioning systems for collection and storage demand much tighter tolerances and much better control.

4.3.1 Temperature control. Temperature control is achieved through heating or cooling the air that is being blown into the environment to be controlled. Sensors in the room detect the conditions and this information is used to control the heating or cooling elements. The interaction with sensors raises some issues that are discussed below.

It is important to note that cooling is the act of removing heat from an area and transferring it to another environment.

An evaporative cooling system, which passes air through a moist environment and so removes heat energy through evaporation, has no place in an archive, partly because it increases the relative humidity. In any case, it is only effective in very dry environments.

A critical fact in the design of environmental control systems is that heating air reduces the relative humidity and cooling air increases the relative humidity. Stable temperature and stable humidity are both of importance and their control is linked: for this reason all temperature control must be coupled with humidity control (3.2.3).

4.3.2 Principles of dehumidification. Almost all storage environments will require dehumidification most of the time in order to remove moisture from the air and so comply with the conditions specified in this publication. The need for humidification, the addition of moisture to the air, is much more rare and, if needed, can be achieved fairly simply. Relative Humidity, which is the most common way to specify moisture in the air, is a percentage measure proportional to the amount of moisture the air could hold at a given temperature and pressure, the latter being dependent on altitude.

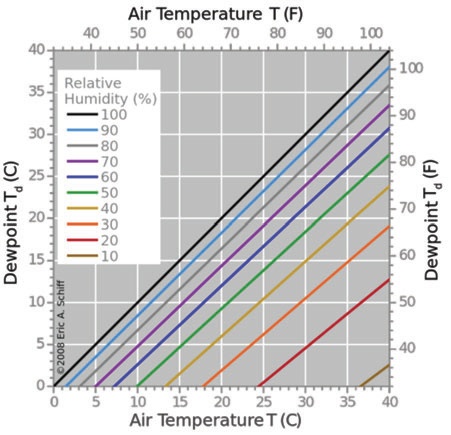

Dehumidification is the removal of moisture from the air to reduce the relative humidity. As was stated above, cooling air increases the relative humidity. If the temperature of the air is made lower it will eventually reach a point at which the moisture in the air condenses to form droplets of liquid. The temperature at which the moisture condenses is known as the “dew point”.

Figure 30: Table of dew point levels. (By Easchiff (own work) [CC-BY-SA-3.0-2.5-2.0-1.0 (http:// creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons)

The most common way to dehumidify an environment is to cool the air being treated to a temperature well below the dew point and, thus, remove moisture from the air as water droplets. The treated air is then heated to the required temperature and the resultant relative humidity is a product of the amount of moisture removed by cooling and the final temperature of the air being treated.

This approach though practical, simple and common, has a number of significant problems. Firstly, the energy cost in cooling and then reheating air is quite substantial and should be considered as a factor in the long term running of any environment. Secondly, the amount of moisture removed from the air is proportional to the temperature differential and a system will often have to be overdesigned in order to be suitable for a wide range of environmental conditions experienced in many places. This is a particular problem in cool environments. And finally, it is very difficult to get accurate control using these sorts of systems, which may lead to cycling such that the system constantly seeks to adjust the conditions and this leads to regular increases and decreases in temperature and humidity, which is in itself detrimental to the storage of collection material.

Desiccant dehumidification is the removal of moisture from the air within a storage area by using a substance (desiccant) that is able to absorb moisture. The desiccant is subsequently heated, outside the controlled area to remove the absorbed moisture after which it can be reused. Such systems can achieve the low levels of dehumidification required for archival storage in most environments and are more energy efficient than the common cooling and heating approach described above.

4.3.3 Sensors are the devices used to detect temperature humidity and other aspects of air quality and condition. Most sensors used in an office environment have tolerances of ±5% or greater. While this is adequate when controlling office environments, when used in critical systems such as archival storage they cannot achieve the tolerances specified in this document.

Sensors detect the conditions in the controlled environment and communicate that information to the air conditioning system. In its simplest form, when conditions are outside of those required, the system switches on; when they are within required conditions the system is turned off. When the system operates in this manner the conditions in the controlled environment can cycle between high and low which has an adverse effect on the materials being stored. In order to overcome this, modern systems with high quality sensors and control technology gradually switch in and out heating and cooling elements leading to a very stable storage environment.

It is common practice to place sensors in the flow of air being extracted from the storage area. However, a poorly designed system can result in pockets or spaces within the storage environment that may be out of specification but undetected by the system (microclimates). Multiple sensors are recommended, with an appropriate agreement on how the sensors are weighted in determining the room conditions.

4.3.4 Air quality and filtering. Air conditioning systems are generally designed to recycle the air in an environment by adding a pre-set proportion of fresh air from outside. The smaller the proportion of fresh air, the simpler and more cost-effective it is to maintain the required conditions. The amount of fresh air is a health issue and most countries have standards that specify a minimum figure of around 10% fresh air. Though storage environment could have a lower proportion of fresh air this would necessitate sensors to determine the build-up of carbon dioxide and other unwanted gases in the storage rooms. It is also likely that the plastics in the media being stored will give off gases, which would build up in such an environment. Therefore, figures near 10% are a suitable compromise between cost and clean air. The flow of air through the room must reach every part in order to prevent any localised build-up of contaminants.

Pumping treated area air into an environment will almost certainly lead to a build-up of dust and other airborne particulates. Air conditioning systems must have filters that remove those particulates. The type of filter and the size of the particulates it removes will depend on the quality of the air both inside and, particularly, outside the building. In addition to well-maintained filters, the amount of dust in an environment can be minimised by maintaining a higher pressure in the room compared to the surrounding area.

For storage areas and laboratories, clean room classes ISO 8, preferably ISO 7 according to ISO 14644-1 should be the target.25

The presence of sulphur dioxide, nitrogen dioxide and oxides of nitrogen, and other gaseous pollutants will degrade the life expectancy of the carriers stored in an environment. Most countries have a specification for air quality, and will recommend particular filter classes.

All filters require regular maintenance and cleaning in order for them to be effective.

25. ISO 8 equals clean room class 100.000 according to former US FED STD 209E, ISO 7 class 10.000.

4.4 Walls, materials, heat transfer, and permeability to moisture

The most effective way of controlling environmental conditions is to build a room with good thermal insulation and constructed with materials that are reasonably impermeable to the transfer of airborne moisture. Standard building materials such as stud plaster walls, bricks, and cinder blocks do not provide very effective insulation against temperature change and allow high levels of moisture to pass into the storage environment. If these materials are used, sealants must be applied to all surfaces, and all gaps, including around doors, must be sealed. The use of airlocks at doorways should also be considered.

One good way to provide a temperature controlled storage environment is to build an insulated envelope or structure within an existing building (4.2). The walls of such an envelope can be made from highly impermeable materials such as rigid aluminium and polystyrene sandwich panels as used to build food storage areas. All entry spaces including doors, electrical and other ducts, screw holes and fixing components must be sealed, as effective vapour sealing of the rooms is vital to their performance. Most places that use this type of building technology report being able to significantly reduce the size and cost of air conditioning plant. In the event of a disastrous loss of power, such storage environments maintain their conditions for a longer period of time.

4.5 How to specify required conditions for a contractor

It is often difficult to specify clearly to a builder or air-conditioning specialist the requirements for a storage environment. Merely stating the target temperature parameters may not produce a successful outcome. It is suggested that the following parameters be considered.

- Set point for temperature and humidity

- Tolerances expressed in values above and below the set point

- Frequency of change (the period of cycle between high and low)

- Rate of change (the gradient of the cycle)

- Amount of fresh air expressed in percentage of cycled air

- Air cleanliness expressed in terms of percentage, or the quality of filter necessary to remove that content

- Air flow throughout the room

- Number of sensors and their placement, and the means of determining the overall conditions

- Energy consumption under a range of conditions

An alternative to the standard supply contract is a performance contract in which the performance is defined in terms of given standards or approaches, but the supplier is commissioned over a given period of time to maintain and manage the system so that it continues to meet those standards. This is likely to be more expensive, but provides a strong incentive for the supplier to meet the specified conditions in the long term.

4.6 Shelving

4.6.1 Material. Today, metal (steel) shelves are generally used. There is no risk in using them for storage of magnetic carriers (3.7.2.3). Wooden stacks, preferred in the 1950s and 1960s, are now discouraged as chemical treatment components may interact with audiovisual carriers.

4.6.2 Shelf loads. Shelves must be sufficiently sturdy to carry the load of audiovisual carriers. The approximate weight of 1 metre of carriers including typical containers is:

| Audio | |

|---|---|

| Replicated 78 rpm (“shellac”) records 25 cm (10”) | 72 kg |

| Replicated 78 rpm (“shellac”) records 30 cm (12”) | 92 kg |

| Vinyl discs 17 cm ( 7”, singles) | 21 kg |

| Vinyl discs 25 cm (10”) | 38 kg |

| Vinyl discs 30 cm (12”) | 54 kg |

| Magnetic tape 13 cm (5”) reels | 12 kg |

| Magnetic tape 18 cm (7”) reels | 18 kg |

| Magnetic tape 27 cm (10.5”) reels/hubs | 48/40 kg |

| Magnetic tape 30 cm (12”) on hubs | 50 kg |

| CDs in boxes (jewel case) | 7 kg |

| Video | |

| Magnetic tape 2” : 30/45/70/90 min | 84/114/120/142 kg |

| Magnetic tape 1” : 75/126 min | 75/87 kg |

| U-matic | 22 kg |

| Half inch format cassettes, average | 8 kg |

| DVDs in boxes | 6 kg |

4.6.3 Storage position. All carriers, discs, tapes, and any cassettes should be stored upright. For discs, shelf separators should be in a distance of half of the discs diameter. Discs should not be tightly packed, however narrow enough to avoid permanent inclined position. Divisions for tapes are usually the same size of their diameter. During the absence of carriers in use, dummy replacements must be used to maintain upright position until carriers are returned.

Only soft, instantaneous discs, like gelatin or Decelith discs, should be stored horizontally in small piles with not more than 10 in a stack.

4.7 Containers

Ideally, carriers should be kept in chemically inert containers designed to provide sufficient protection against mechanical damage through normal handling and protection against light. With the advancement of conservation research over the past decades, the autocatalytic actions of several polymer degradation processes have been understood. Consequently, the use of airtight storage is not recommended as it could trap endogenous degradation by-products, thus increasing the rate of degradation. Generally, dust prevention should be achieved by proper insulation and air filtering of the entire storage environment. This will allow air to flow around the carriers which will help retard, if not prevent, autocatalytic deterioration. Where effective dust prevention of the entire storage area is not possible, a decision for carrier related dust prevention will depend on the relative risks of threats from internal changes in the carrier versus unavoidable external threats.26

The materials preferred for containers designed to replace damaged or inadequate original ones are polypropylene and polybutylene for magnetic tape boxes, polyethylene bags or acid free paper sleeves for vinyl discs, and acid free paper sleeves for shellac records. For cylinder storage, the Association for Recorded Sound Collections (ARSC), in collaboration with the Library of Congress, has developed an Archival Cylinder Box27.

Original containers or wrapping materials often suffer from a variety of problems: an acidic cardboard may have been used for tape boxes and disc sleeves; acidic paper for liner notes and booklets for LPs and CDs, as well as for inlays for notes for all kind of blank audio and video cassettes. In the early days of LPs, PVC sleeves were sometimes used which may cause plasticiser migration to damage LP surfaces.

Having optimisation of life expectancy in mind, ideally all carriers should be separated from inadequate original containers, wrapping and other accompanying materials. All such action should, however, be carefully considered and the improvements in storage conditions balanced against the financial and great organisational challenges such a task may demand. The great majority of containers and accompanying materials are themselves carriers of information that form a constituent part of the total document. Any loss or disorder through inappropriate cross referencing of separated parts of the document will generally cause much greater damage to the integrity and usefulness of the material than any theoretical optimisation of life expectancy. Generally, therefore, it is recommended that such exchanges be restricted to cases of obvious and immediate threat, such as PVC or other inadequate sleeves for LPs, or the removal of plastic bags from CA tapes.

26. Archives in moderate climatic zones may thus arrive at different solutions than those in hot and arid environments.

27. This container is designed for storing a single “standard-size” cylinder phonograph record. For details, contact Bill Klinger (Chair of the ARSC Cylinder Subcommittee) at klinger@modex.com.

4.8 Transport

Transport requires adequate measures against shock, climatic changes, and stray magnetic fields.

4.8.1 Shock prevention. The most shock sensitive carriers are cylinders and shellac records. These require adequate shock absorbing packaging, particularly when carriers are shipped by post or freight. Cylinder packing requires a careful balance between the prevention of any movement inside their boxes, movement of boxes inside outer containers, and appropriate measures for shock absorption. Additionally, attention must be paid to the prevention of elevated temperatures, specifically through unnoticed sun radiation. Because of their importance, transport of cylinders is often entrusted to art transport specialists (4.8.4). Shellac records require a box-in-box packaging. Inner and outer boxes shall be made from strong cardboard, separated in all directions by a layer of styrofoam or similar shock absorbing materials. It is imperative that discs inside the inner box are absolutely tightly packed to prevent any movement against each other. Vinyl discs are less shock sensitive, but an equal level of protection is wise to prevent damage to their covers. The same measures, particularly tight packing, are imperative for magnetic tape on open hubs to prevent any movement within the wind of the tape or movement of the tape pack on the hub or even slipping off the hub.

4.8.2 Heat and humidity. Any transport will expose carriers to climatic conditions outside optimal storage parameters. As a first measure, a method and routing of transport, including seasonal considerations, should be chosen to minimise these risks by avoiding exposure to extreme climatic conditions. Additionally, adequate packing must prevent unavoidable temperature changes and exposure to humidity. A typical threat is moisture penetration of carriers after long periods in cold environments and subsequent exposure to warmer and more humid conditions. Examples include transport in cargo holds of airplanes and landing in hot and humid climatic zones. Countermeasures include the provision of sufficient thermal insulation in the packing material during transport and, after transport, the carriers should be aired to prevent trapping high moisture levels and the temperature allowed to slowly return to normal. Whenever possible, audiovisual carriers should be transported in the cabin of air planes. Transport in unpressurised cargo holds should be avoided whenever possible.

4.8.3 Stray magnetic fields. The magnetic fields produced by metal detectors at airports for checking hand luggage are normally too weak to influence the recorded signals of audio or video tapes. As detectors for luggage to be carried in the hold may produce stronger magnetic fields, it is generally recommended that recorded magnetic tapes be transported as hand luggage. There is no information, however, on possibly dangerous stray magnetic fields with other transport systems, such as electrical railways, subways and buses, or other electrically driven transport machines. Such risks may be very low, as no incidents have been reported that would point to such sources of danger. However, in order to eliminate this risk, it may be advisable to protect magnetic carriers of exceptional value by carrying them in metal boxes of highly permeable materials.

A greater threat, however, may be the increasingly common electrically powered cars. Before concrete measurements of their stray magnetic fields are available, great caution is advised. It is important that tapes should be carried in metal boxes, or the use of such vehicles avoided until more is known about the possible dangers.

4.8.4 Cooperation with specialised transporters. The transport of large quantities of carriers, e.g. the relocation of whole collections, should be jointly planned and arranged with specialists in the field of transport of art treasures.