Measurement of Decomposition

Two main approaches are of interest to archivists:

- Physical means, such as optical characteristics, viscometry, cohesion/shedding, adhesion, buildup of sticky residue of heads and guides;

- Chemical analysis, inc chromatography, infra-red or mass spectra, nuclear magnetic resonance (NMR), solvent extraction, and pH determination.

The main drawback with relying on visible indications of decomposition or physical symptoms evident during playback or spooling, is that they often don’t show up until it is too late - once binder failure has occurred. Despite this fact, it is still too often the primary or only means of detecting binder decomposition. Indeed, manufacturers still advise clients that this is the simplest and most reliable means of determining the state of tape collections 6. Certainly it is the ability of magnetic tapes to retain their physical integrity for running on a tape transport to reproduce a faithful signal which is of ultimate concern.

Chemical condition and quantitative measurement of binder condition are of more than just academic interest, however; they serve as an early warning of problems which axe building up, and allow time for planning and implementing the task of treating and dubbing original or historical tapes, particularly when work on large collections must be prioritised. In conjunction with accelerated aging, stability testing is an important means of selecting formulations for recording and acquiring new material, as well as dubbing the sonic content of older, unstable carriers.

Of all the available options, solvent extraction (SE) and pH are of particular interest, and have been used in recent years at the NFSA. Spectral analysis and chromatography are powerful tools for those fortunate enough to have the facility, although results often need careful interpretation. They can be useful for initially testing new or unknown formulations to help in analysing the different constituents. Binders in the 1970s have failed prematurely due to the inclusion of low - as well as high- molecular weight polymers, despite an apparently acceptable average molecular weight. Manufacturers have cited more accurate analysis of the spectrum of molecular weights in quality control of raw materials as a means of improving stability of binder formulations 7,8. SE and pH measurement can be routinely implemented more readily with simpler equipment and less skilled personnel, provided that they are adequately trained.

Solvent Extraction

As PE-U binders degrade, scission of ester linkages occurs by hydrolysis, the polymer chains become shorter and the binder is said to lose molecular weight. A characteristic of such lower molecular weight polymers are that they become gummy or sticky rather than retaining their strength and integrity as an elastomer. Whereas the properly cross-linked binders are largely insoluble, the lower molecular weight residue will literally wash away in solvents such as acetone and methyl ethyl keytone (MEK) (Fig.4). A technique put forward by Cuddihy 9 in 1980 was to weigh a sample of tape before soaking in solvent and dissolving out the low molecular weight binder residue, then re-weighing the sample to determine by difference (percentage w/w) the amount of broken down residue lost in the process of extraction.

Since a PE-U tape in good condition has only a small percentage of solvent-extractable residue, typically 0.5-1%, whilst sticky unplayable tapes are often closer to 4 or 5%, it is possible to obtain a rough indication of binder condition even without a reference level for a particular formulation. Similarly an artificially aged tape showing an increase of more than a few percent extractables is inclined to instability, particularly when one accounts for the nature of additives such as plasticisers and fatty-acid lubricants. If a collection of tapes is properly monitored, with periodic measurements taken and records kept (along with control samples) from when new or prerecorded tapes first enter the Archive, a pattern of understanding may be developed which can serve as a basis for treating and dubbing material before it reaches a critical state. With experience, SE then can be correlated to playability for tapes of a given age and formulation.

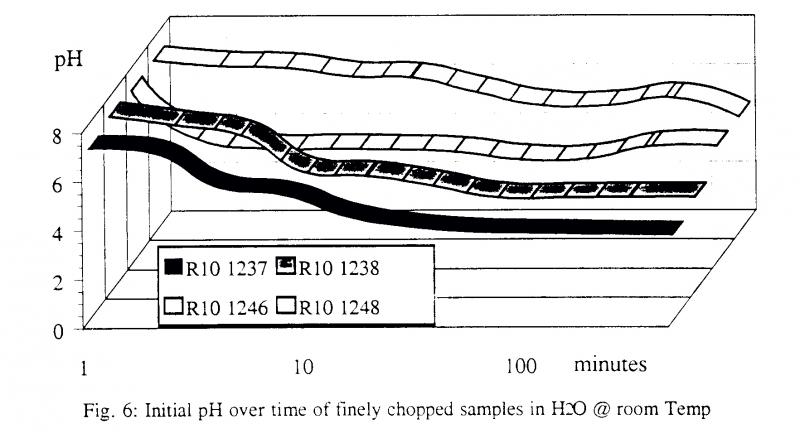

Our own test method consists of weighing then immersing 50-100mm long samples in glass vials containing 20-50ml HPLC-grade acetone. After removal from the solvent and drying in air, the final weight is used to calculate percentage weight loss. Initial readings over logarithmic time intervals indicated that 20-30 minute immersion followed by 1-5 minutes drying time was sufficient to give stable, repeatable measurements (Fig.5).

Care and skill is required for solvent extractions on fragile tapes including those with PVC binders, which lose oxide and/or backcoat in the process. Techniques for filtration and evaporation can be used to avoid the apparent variation which has confused some attempts at such analysis. A team at the U.S. National Bureau of Standards produced similarly variable results by using tetrahydra furan (THF) which dissolves stable, high molecular weight polymers rather than acetone-soluble residue alone 5.

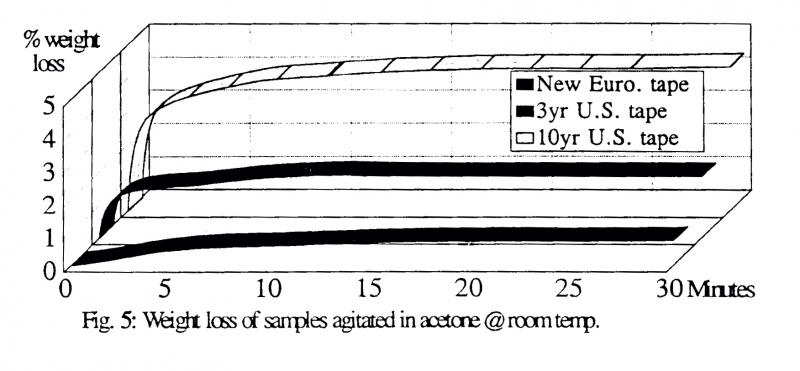

pH Determination

An alternative process is used to complement and verify results of solvent extractions and provide added indications of PVC binder condition. As previously explained, dehydrohalogenation of PVC produces HC1, whilst hydrolysis of PE-U produces carboxylic acids. Acids are normally measured on an inverse logarithmic scale of H+ ion concentration simply called pH. A technique commonly used for testing film supports 10 involves soaking finely chopped tape samples in distilled H20, then measuring pH. In our initial trials we arrived at H20:tape ratio of 10:1 w/w, over an immersion time of 2 hours with constant agitation (Fig. 6).