8.1 CD/DVD Recordables

8.1.1 Introduction

8.1.1.1 Recordable CD (CD-R) and recordable DVD (DVD-R/+R), have become integral in the recording and distribution of many types of audio and audio-visual materials. Though the CD and DVD are now only one of many types of more affordable and reliable storage technologies, the format remains popular for many reasons, amongst them their ease of use and common familiarity. The CD was initially marketed as the perfect permanent carrier, but this was soon shown not to be the case when many of the early discs failed. Even though subsequent technological development has improved on many of the early manufacturing faults, no credible claim can be made to permanence. In fact, digital archiving experts commonly acknowledge that no carrier is permanent.Instead,the processes of acquiring data, transferring to storage systems and managing and maintaining the data, and providing access and ensuring the integrity of the stored information, presents a new range of risks that must be managed to ensure that the benefits of digital preservation and archiving are realised. Failure to manage these risks appropriately may result in significant loss of data value and content.

8.1.1.2 Recordable CDs and DVDs are often chosen as archival carriers, however, the risk of failure of a storage system based on this type technology is high when compared to other approaches. An integrated digital mass storage system with suitable digital repository management software is recognised as the most appropriate for the long term sustainability of data. There may, however, be circumstances where a collection curator may make a decision to use optical disc for storage.

8.1.1.3 Bearing in mind these constraints, it is possible to use recordable optical disks as reliable carriers for a short period of time providing the following recommendations are carefully adhered to.

8.1.2 CD-R and DVD-R Recording Formats

8.1.2.1 There are two different approaches to the encoding of audio and video on recordable CDs and DVDs, either as an audio “stream”, or as a data file. In the first of these approaches sound is recorded as CD-DA formatted audio, which makes them playable in ordinary CD-players, or to encode it in MPEG formatted DVDs, which may not all play in standard DVD-players. Stand alone recorders will only record these formats, though computer based equipment may optionally produce disks in these standard domestic forms. The use of these formats severely restricts the possibility for on-line access and choosing this option may possibly create a migration problem the next time you need to change carrier. It is not recommended that audio streams be recorded for long term storage.

8.1.2.2 The alternative, recording a file using a computer based audio editing system and writing that file to CD-R or DVD-R is a more reliable approach. Recording files on a 650 MB CD-R allows 59 minutes audio storage for 48 kHz 16 bit linear PCM files, and 39 minutes for 48 kHz 24 bit linear PCM files. Recording the same format files on a 4.7 GB DVD-R allows up to 6 hours of audio storage. For this reason the writing of data files is recommended. Because of the simplicity and ubiquity of linear PCM (interleaved for stereo) IASA recommends the use of a .wav or preferably the BWF .wav files (EBU Tech 3285) if recordable CDs and DVDs are selected as the target format.

8.1.3 Recordability, rewritability, erasability and accessibility

8.1.3.1 CD-R, DVD-R and DVD+R discs are dye-based recordable (write once) discs, but not erasable. CD-RW, DVD-RW and DVD+RW discs are phase-change based repeatedly rewritable discs permitting erasure of earlier data and recording of new data in the same location on the disc. DVD-RAM discs are phase-change rewritable discs formatted for random access, much like a computer hard disc.

8.1.4 Recordable CD and DVD Description

8.1.4.1 CD-Rs and DVD-/+Rs store data in line with microscopic grooves running in a spiral from the centre of the disc to its periphery. All CD/DVD drive types use laser beams to scan these grooves. They differ in the wavelength of the laser beam: DVDs use a narrower track pitch of 0.74µm, compared to 1.6µm on CDs. DVD also takes advantage of new modulation and error correction methods not available when the CD was specified.

8.1.4.2 The mechanical dimension of CDs and DVDs are equal: 120mm in diameter, and 1.2 mm thick. The DVD, however, is made up of two discs of 0.6mm thickness, which are bonded together.

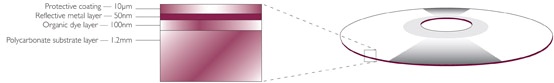

8.1.4.3 CD-R and DVD+R consist of three layers: the clear polycarbonate substrate, the dye layer and the reflective layer. In CD-R the reflective layer is close to the label side of the disc and an additional protective lacquer surface layer covers the fragile surface. DVD-Rs reflective layer is situated in the middle of two polycarbonate layers. In the recording process, a laser of much higher intensity than the reading laser “burns” the organic dye according to the coded signal, leaving a row of minuscule transparent and non-transparent areas aligned along grooves in the disc. All recordable CDs and DVDs contain a reflective layer that allows a reading laser to bounce off the CD/DVD and to be “read” by the pickup sensor in the CD or DVD replay device. Many metals are suitable for use as a reflective layer, although only two have been in widespread use on recordable CD and DVD, gold or silver. The combination of the recorded dye groove with the reflective layer modulates the reading laser in the same way as the injection moulded pits and lands and the reflective aluminium layer of a CD -ROM.

8.1.4.4 The three common organic dyes used in recordable discs are cyanine, phthalocyanine and azo. In a recordable CD each dye gives the media its distinctive look depending on which metal is used for the reflective layer; cyanine (blue) dye appears green on gold media and blue on silver media; phthalocyanine (clear light green) dye appears transparent on gold media, but light green on silver media; azo (deep blue) has developed into different shades of blue, the original being a deep blue, and the more recent Super Azo a brighter shade of blue. Because the dye layer is applied so thinly in recordable DVD the type of dye used on recordable DVDs is not easily distinguishable. However, manufacturers of recordable CD and DVD encode information about the type of dye in the polycarbonate layer. The CD and DVD burners use this information to calibrate laser power, and with suitable software the information can be read by users to more accurately describe aspects of the disc itself. This data may be read by ISRC and ATIP code viewers such as CD Media Code Identifier (http://www.softpedia.com/get/CD-DVD-Tools/CD-DVD-Rip-Other-Tools/CDR-Med... ). This tool allows users to view information such as dye type, disc manufacturer, capacity, write speeds and media type. Clover also provides freeware device, IRSCView (http://www.cloversystems.com/ISRCView.htm) will display the Table of Contents, Control Codes, and ISRC codes on Audio, Mixed Mode, and Enhanced CDs. It provides much less manufacturer information than the CD Media Code Identifier.

Fig 1 Section 8.1: A schematic view of a CD-R (not to scale).

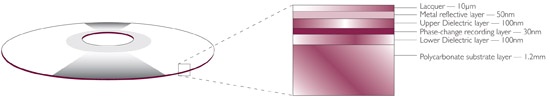

Fig 2 Section 8.1: A schematic view of a CD-RW (not to scale).

8.1.4.5 Rewritable CDs and DVDs operate on an entirely different principle. Rewritable discs are erasable and can be rewritten, albeit a finite number of times. The recordable layer is made of germanium, antimony and tellurium. A laser is used to heat the surface to two set temperatures. The higher temperature is known as the melting point (approximately 600 degrees centigrade), while the lower level temperature (approximately 350 degrees centigrade) is described as the crystallisation temperature. Heating the disc, and controlling the cooling rate, produces a track of amorphous or crystalline areas. Due to the different reflectivity these areas will be interpreted by the reading laser like the pit/land structure of a CD-ROM. Earlier rewritable discs and drives could only be written at relatively low speeds and this was encoded and implemented in the first generation of drives and standards. More recent developments have provided a mechanism for burning data onto rewritable discs at a higher speed. Though the older drives will read a new high speed rewritable disc, only the latest generation of disc burners will write a disc of the latest formulation.

8.1.4.6 No trustworthy analysis of the medium or long term reliability of RW discs has been undertaken. Preliminary investigations suggest that the film layer containing the encoded information may degrade at a quicker rate than dye based CD-Rs (Byers 2003:9), other commentators disagree. From a purely practical point of view, CD and DVD rewritable may present a greater risk if used for preservation purposes as they may be overwritten by accident with a resulting loss of the original files.

8.1.5 Optical Disc Standards

8.1.5.1 Adherence to standards is the mechanism by which discs are writable or playable on different manufacturers’ machines. The manufacturers have the responsibility to make the disc in accordance with the particular standards. These standards, however, are not formulated with regard to longevity or reliability of the carrier, but only format interchange. Consequently, a disc recorded and playable on a particular machine may in fact be borderline, or even fail to meet the standard that applies. So, although the manufacturers are responsible for the formulation of a disc, the potential life of any information storage media will only be realised if end users take responsibility for producing a suitable digital copy that falls within the parameters set by those standards. Relying on the technology to meet the standards is not sufficient to ensure optimum disc life.

8.1.5.2 This requirement to ensure that the digital information stored on an optical disc is produced in accordance with the standards is exemplified by the issue of disc and burner compatibility. The standards apply to the recording media rather than the replay and recording technology. Philips warns manufacturers of disc burners that they “must implement a writing strategy giving acceptable results”. However, this can be interpreted in a number of ways, resulting in varying compliance. Philips/Sony attempted to address this issues with the MID (manufacturers identification code). The nature of the production of recordable media means, however, that the only information MID really records is the name of the manufacturer of the stampers that are used in the production of discs. Consequently, it has done little to resolve the issue of disc/burner interaction, which remains something of a problem.

8.1.5.3 The standards that apply to Recordable CD include Orange Book Part II: CD-R Volume 1 CD-WO (CD write once) also known as CD-R standard describing 1x, 2x and 4x nominal CD speed. Orange Book Part II: CD-R Volume 2: Multi-Speed CD-R (CD Recordable) describing the speeds up to 48x nominal CD speed. Orange Book Part III: CD-RW Volume 1 CD-RW (CD Rewritable) describing 1x, 2x and 4x nominal CD speed. Orange Book Part III: CD-RW Volume 2: High Speed CD-RW (CD Rewritable) describing 4x and 10x nominal CD speed. Orange Book Part III: CD-RW Volume 3: Ultra Speed CD-RW (CD Rewritable) describing 8x and 32x nominal CD speed. Green Book. Compact Disc Interactive Full Functional Specification and White Book Video-CD Specification. There are also standards for other proprietary CD formats.

8.1.5.4 The standards that apply to Recordable DVD include ISO/IEC 16824:1999 Information technology -- 120 mm DVD rewritable disk (DVDRAM). ISO/IEC 16825:1999 Information technology–Case for 120 mm DVD-RAM disks. ISO/IEC 17341:2004 Information technology -- 80 mm (1,46 Gbytes per side) and 120 mm (4,70 Gbytes per side) DVD re-recordable disk (DVD+RW ). ISO/IEC 17342:2004 Information technology -- 80 mm (1,46 Gbytes per side) and 120 mm (4,70 Gbytes per side) DVD re-recordable disk (DVD-RW). ISO/IEC 17592:2004 Information technology -- 120 mm (4,7 Gbytes per side) and 80 mm (1,46 Gbytes per side) DVD rewritable disk (DVD-RAM). ISO/ IEC 17594:2004 Information technology–Cases for 120 mm and 80 mm DVDRAM disks. ISO/IEC 20563:2001 Information technology -- 80 mm (1,23 Gbytes per side) and 120 mm (3,95 Gbytes per side) DVD-recordable disk (DVD-R). ISO/IEC 16969:1999 Information technology–Data interchange on 120 mm optical disk cartridges using +RW format–Capacity: 3,0 Gbytes and 6,0 Gbytes . ISO/IEC DTR 18002 – DVD File System Specifications. ISO/IEC 13346, Recordable/ Rewritable Volume and File Structure (ECMA-167) and DVD+R - Recordable Optical Disks, 4.7 GB, recording speed up to 4X (ECMA-349).

8.1.5.5 These standards are in addition to those specified in section 5.6.2 Standards.

8.1.6 System Description, Complexity and Cost

8.1.6.1 As noted in Chapter 2, Key Digital Principles, almost all recent generations of computers have sufficient power to manipulate large audio files. Providing all the system standards regarding the equipment used for conversion and ingest of audio data set out in Chapter 2 are met, the system complexity and the degree of expertise required to run such systems is not much greater than is necessary for desktop computer operation. Many reliable CD and DVD burning programs are available that meet the standards required.

8.1.6.2 The only additional equipment required for the production of recordable CD or DVD is the burner, or drive. The drives may be mounted in the computer cabinet or separate though attached to the computer. The drives communicate with the computer through protocols such as IDE and SCSI for internal drives,and Firewire or USB for stand-alones. Certain drives produce lower error rate CD-Rs and DVD-Rs than others, and it is the responsibility of staff to assess and analyse the results of the disc burning before purchasing (see Section 8.1.9 Errors, Life Expectancy and Testing and Analysis).

8.1.6.3 The low system complexity, easy availability of technology, and inexpensive media makes the CD-R and DVD-R a popular option with sound archives. However, as demonstrated in Chapter 6 Preservation Target Formats and Systems, the cost of a more reliable data storage system is less if averaged across the whole collection, even for quite small collections.

8.1.7 Disc and Drive Compatibility

8.1.7.1 Compatibility between discs and drives may well be an issue when recording data on recordable and rewritable CDs and DVDs. Situations often occur where certain discs produced on a particular drive may produce very poor quality duplicates,or may be unreadable on other drives. Testing of this issue has revealed that this failure rate may be very high. An International Standards Organisation project – ISO N178 Electronic imaging – Classification and verification of information stored on optical media, may address the specific problem of drive compatibility.

8.1.7.2 The reason for poor performance may be related to a number of factors: Early drives do not have the laser power to calibrate on later types of discs; Drives designed for dye based discs cannot write, and often cannot read, rewritable discs; Software issues, aging parts, particularly lasers, and particular implementations may all produce inadequate results;The calibration information encoded into the polycarbonate substrate may not necessarily be precisely accurate. However, even taking these issues into account, a significant number of failures occur which are only explained as technical incompatibilities. The equipment manufacturers’ slightly varied implementation of the disc read standard and the variation in the discs quality mean that a situation can occur where discs and drives are incompatible to the extent that the particular combination may produce failed discs on a particular brand, or batch, of discs.

8.1.7.3 In order to ensure that drives and discs are compatible, it is recommended that a range of brands of reliable and reputable discs are recorded on the selected drive, and these discs are tested to determine error levels. This is discussed in the sections below.

8.1.8 Disc Selection

8.1.8.1 There are three basic types of dye used on write once recordable discs, phthalocyanine, cyanine, and azo. Manufacturers of phthalocyanine discs claim a longer life for their product than the competitors. Some, though not all initial testing supports this view. Some manufacturers use Azo dyes in discs that they claim are archival. Cyanine was the first dye type developed for optical disc recording, and is generally recognised by most manufacturers as having a shorter life expectancy (LE). Dye type, though significant, is only one of the factors determining the life of the media.

8.1.8.2 The variation in the amount of dye used in the dye layer, a result of the manufacturers’ race for even higher recording speeds and higher density recording, is a contributing factor in the long term failure of recordable optical media. Recording speed has increased from X1 to X52 and is still rising, as the recording density has gone from 650MB to 800MB for CD-Rs. It should be noted that discs optimised for high speed recording use less dye, which may indicate a shorter life expectancy. DVD-R uses less dye as a matter of course, as the data rate when writing to a recordable DVD is much higher than for CD-R.

8.1.8.3 It is not, however, just a matter of reducing speed; if discs with a denser dye layer, optimised for writing at lower speeds, are written at higher speeds, they deliver a worse error rate. Though manufacturers indicate the maximum recording speed, writing at that maximum speed may not achieve adequate results. There is an optimum writing speed at which the disc produced obtains the best possible technical measurement for performance. Identifying this speed is best done by trial and error measurement using a reliable disc tester. Typically, the best results will be achieved on a dense dye layer disk written at around 8 times speed.

8.1.8.4 At best, the quality of blank recordable CD and DVD media can be described as variable. The recordable CD and DVD- manufacturing industry has become a market place driven by narrow profit margins and large quantities. Recordable CD and DVD manufacturing equipment has become smaller, cheaper and more self-contained. As a consequence, the production of reliable data carriers for the quality market has largely been replaced by manufacturers of recordable CD and DVD, producing recordable CD and DVD for the low cost market.

8.1.8.5 Many discs that appear to be reputable brands may turn out to have been manufactured by a second party and repackaged for sale. A recordable CD or DVD manufacturer can manipulate the dye, reflective layer and the now expensive polycarbonate components to reduce price or control quality. As a general rule, it has often been recommended that only reliable brand recordable CD and DVD are purchased, however, testing has revealed a range of compliance with agreed standards even amongst them. Instead, it is recommended that the responsible individual or institution insist on dealing with a supplier that is open about the importer or manufacturer they deal with, and who is able to provide contact with the relevant technical personnel in the manufacturing company. Discs that fail the standard specified below should be returned.

8.1.8.6 It is quite difficult to identify the best quality media without high level analysers (Slattery et al., 2004). In most practical circumstances discs must be recorded before they can be tested. Some very high quality CD and DVD testing equipment will analyse an unrecorded disc, but most testing is carried out by recording a test signal and analysing the result. ISO 18925:2002,AES 28-1997, or ANSI/ NAPM IT9.21 is a standard test method to establish the life expectancy of compact discs, and ISO 18927:2002/AES 38-2000 is a standard for estimating method for estimating the life expectancy based on the effects of temperature and relative humidity for recordable compact disc systems. As temperature and humidity aging does not always produce clear results, other approaches have concerned themselves with the susceptibility of recordable dye based discs to light exposure with age, and some manufacturers have undertaken testing in this area. There is, however, no standard for this (Slattery et al., 2004).

8.1.8.7 Summary of Disc Selection

8.1.8.7.1 Purchase a range of best quality discs, based on market research.

8.1.8.7.2 Purchase more than one of each type. (Though price is not necessarily an indicator, always remember that the cost of even the most expensive discs is small compared to the value of the data.)

8.1.8.7.3 Under controlled conditions record some data on each of the discs.

8.1.8.7.4 Test to see which discs perform best with regard to specification in this document. All discs must exceed the recommended quality standards recommended below (see Table 1, Maximum error levels in an archival CDR).

8.1.8.7.5 Test at a number of different writing speeds.

8.1.8.7.6 Keep disc/burner compatibility in mind: different burners may yield different results.

8.1.8.7.7 Choose the three best discs, from at least two dye types (phthalocyanine and azo).

8.1.8.7.8 Record identical copies of the data on the three chosen discs.

8.1.8.7.9 Ensure that delivered supplies of chosen discs are identical with tested sample discs.

8.1.8.7.10 Repeat tests each time a batch of discs are purchased.

8.1.9 Errors, Life Expectancy and Testing and Analysis

8.1.9.1 The only way to know the condition of a digital collection is constant and comprehensive testing. This cannot be stated too strongly; no collection using CD-R or DVD-R/+R as an archival carrier should be without a reliable tester. The error correction capability of most replay equipment will mask the effects of degradation until the errors are well into the uncorrectable region.When this point is reached, all subsequent copies are irreversibly flawed. On the other hand, a comprehensive testing regime allows for best possible planning of preservation strategies by acting on the known, objective and measurable parameters that digital archiving make possible. In the well-documented digital archive, metadata will record the history of all objects, including a record of error measurements and any significant corrections.

8.1.9.2 Life expectancy of CD-R or recordable DVD is a many varied topic. To most end users, a CD-R or DVD-R/+R reaches the end of its life when the drive no longer reproduces the data written on the disc, but because drives are not governed by standards, a CD/DVD that will not play on one drive may well play on another. There are innumerable examples of this. The ANSI/NAPM IT9.21-1996 – Life Expectancy of Compact Discs (CD-ROM)- Method for Estimating Based on Effects of Temperature and Relative Humidity, discusses many of these issues. Alternately, some standards and suppliers specify an acceptable Block Error Rate (BLER). BLER is the number of erroneous blocks per second measured at the input of the C1 decoder (see ISO/IEC 60908) during playback at the standard (x 1) data rate averaged over a 10 second measuring period. Standards ISO/IEC 10149 and ANSI/NAPM IT9.21-1996, or Red Book standard, specify a maximum BLER rate of 220. The standard for recording general data on CD, otherwise known as Yellow Book standard, specify a BLER of 50. For data purposes this lower level is vital.

8.1.9.3 Studies have shown that BLER alone is not a very useful measure when determining LE, because defective discs may exhibit BLER well under 220, or indeed under 50. It is necessary to measure other test parameters, among them E22, E32 (uncorrectable errors), and frame burst errors (FBE, sometimes called Burst Error Length or BERL), which are valid end-of-life indicators.When these parameters exceed the limits specified below, it indicates a need for immediate duplication, assuming the disc containing archival information is still readable.

8.1.9.4 Errors in archival CD-Rs should not exceed that specified in the table below. These are maximum levels after which CD-Rs must be copied. In practice error levels much lower than this are achievable and preferable, and must be met in order for the disc to have any archival life before recopying becomes necessary. A BLER average of 1 and a peak level of less than 20 are easily achievable. Jitter is also a useful diagnostic indicator of the quality of the data recorded on a CD and should be measured after writing. The 3T jitter values should not exceed 35 nS (Fontaine and Poitevineau, 2005).

| Frame burst errors FBE | <6 |

| Block error rate BLER average | < 10 |

| Block error rate BLER peak | < 50 |

| E 22 (correctable errors) | 0 |

| E 32 (uncorrectable errors) | 0 |

| 3T Jitter | <35nS |

Table 1 Section 8.1, Maximum error levels in an archival CD-R

8.1.9.5 The construction of a DVD is significantly different to that of the CD, and though there are many aspects in common the criteria that applies to CDs does not necessarily apply to the DVD. Jitter in DVDs is customarily measured in percentages. Though measured differently, the actual jitter measurement is largely equivalent in the two disc types, the main error measurements, however, are quite different. The two main DVD error measurements are Parity Inner Errors (PIE) and Parity Outer Errors (POE). Industry standards state that the POE should be zero. Other types of error measurement are defined, but at the time of writing no agreed threshold for archival purposes has been developed. The DVD specification also states that any eight consecutive ECC blocks (PI Sum8) may have a maximum of 280 PI errors and jitter should not exceed 9%. However, with regard to the use of recordable CD, archival experience and testing has led to a recommendation in maximum error levels that is approximately 25% of the red book recommendations. An extrapolation on the DVD figures would lead to a recommendation of a maximum of 70 PI errors in any eight consecutive ECC blocks. It is important to recognise that a distributed range of tests on DVD recordable in archival situations has not been undertaken to assess the validity of these figures.

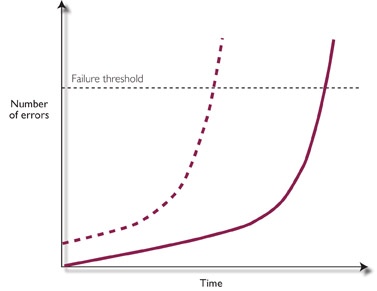

8.1.9.6 Initial investigations indicate that recordable CDs do not necessarily proceed to failure in a linear way and that as a consequence small change in initial error rates could have a greater effect on useful life of the disc. There are several tests that have indicated this to be the case (Trock, 2000), (Bradley, 2001), however, there has not been an extended examination of this proposition. A “longitudinal” examination of recordings over time coupled with artificial aging experiments might bring better information on the factors of disc stability. A factor which continues to add to the lack of consistent research is the lack of an agreed standard for the production of CD/DVD-drives.

8.1.9.7 The comparison of the solid black line to the dashed line (see Fig 1 Section 8.1 overleaf) illustrates that the better the initial recording is the longer the expected lifetime will be. There are several tests that have shown this to be the case (Trock JTS 2000, Bradley IASA/SEAAPAVA 2001), however, there is no empirical proof that this is the case. The dashed line, starting at a higher error level, decays at the same rapid rate, but starting earlier reaches failure level in a much shorter period of time. A “longitudinal” examination of recordings with time, aging experiments, might bring better information on the factors of disk stability. A factor adding to the lack of consistent research is the fact that there is no standard for the production of CD/DVD-drives.

8.1.9.8 Being a composite item containing, amongst other components, organic dyes or other chemical compounds, these optical carriers are bound to deteriorate due to slow chemical reactions. Choosing optical discs as the target medium entails the requirement to set up a monitoring program for the discs and a procedure for recopying discs that approach the limit of LE. The use of recordable and rewritable CD/DVDs as archival carriers cannot be advocated unless a strict testing and monitoring program is set up. It should be noted that testing and analysing, though absolutely necessary, will be time consuming, adding long-term costs to the archival solution.When planning an archival strategy, these costs should be included. Logs of test results should be stored, and occasional testing, perhaps annually, can be carried out on statistically appropriate number of stored discs carrying archival information.When the error rate is shown to be increasing, a transfer to a new carrier can be undertaken of all the discs of that age or type.

Fig 1. Section 8.1: Accumulated errors in a CD-R over time

8.1.9.9 Summary of Testing

8.1.9.9.1 Test all discs when writing.

8.1.9.9.2 Reject any discs which fail to meet specification.

8.1.9.9.3 Store the relevant test records of all discs.

8.1.9.9.4 Undertake a regular testing of a statistically significant number of stored discs of each different batch of products. 8.1.9.9.5 Undertake a recopying of discs when error rates increase.

8.1.10 Testing of Existing Recorded Discs

8.1.10.1 If data on recordable CD or DVD was not tested at the time of creation, it is critical that tests are made of their current state. Discs must be subjected to rigorous error testing as their current error rates play a major part in determining their further life expectancy. If error rates are measured above the levels expressed in table 1, contents should be immediately transferred to new media.

8.1.11 Testing Equipment

8.1.11.1 Professional testing equipment with dedicated, or at least specified, drives is recommended for accurate testing DVDs and CDs. Such systems are more expensive but are necessary if accurate, reliable and repeatable error measurement are to be achieved. The testing should at least comply with ISO 12142 Electronic imaging – Media error monitoring and reporting techniques for verification of stored data on optical digital data discs. Such testing will not, however, address the problem of the lack of standardisation of optical disc drives. There is at the moment of writing, a standards project with the International Standards Organisation, ISO N178 Electronic imaging – Classification and verification of information stored on optical media, which may address the specific problem of drive compatibility. Although there is test software available on the web as shareware, such software should be carefully evaluated before being relied on in an archival environment. Such software based systems depend on the accuracy of the non-standard computer drives. If a testing system based on computer drives is required, then a proprietary system supplied by the disc manufacturer stands a better chance of being useful. At least one CD/DVD burner company does provide software that allows their drive to be used for the purposes of testing. The results of any testing system that depends on the CD burning drive should be checked against a known, calibrated testing system to ensure adequate compliance.

8.1.11.2 Disc test equipment which accurately measures only the parameters specified in this guidance document are commercially available and of good standard. However, the figures provided by testing these parameters are suitable only for identifying problems. Analysis of problems probably requires access to a high analytical CD and DVD testing facility. It is useful to gain access to this type of equipment, by renting or borrowing, when solving problems, selecting blank media or calibrating in house testing facilities.

8.1.11.3 Kodak, in their web-document “Permanence and Handling of CDs” (Kodak 2002) claim that 95 % of their CD- Rs will maintain a data lifetime of a hundred years in an office environment. The results of these tests are often held to be suspect by archivists, and many have found it difficult to reproduce the tests and achieve the same results. This may be due to different interpretation of the figures and some argument about the validity of the method of estimating lifespan. Even if these tests proved to be true, and in the unlikely event that CD drives are still available 100 years hence, a 5% failure rate is unacceptable in an archive. This conclusion also supports the requirement of an error monitoring program.

8.1.11.4 Accurate, High Quality Production Testers

8.1.11.4.1 At the time of writing the cost of accurate, high quality production testers starts at around US$ 30,000 for the basic models and increases to over US$ 50,000 for many devices. The cost is incurred in the high quality reference drives which are a necessity for accurate and repeatable testing. All testers are aimed at the market of optical disc manufacturers for production control purposes. Actual prices depend on the scale of measurable parameters, many of which are not relevant for testing recordable optical discs as to their archival reliability. Currently, there are three producers of high quality testers:Audio Development (http://www.audiodev.com/), DaTARIUS (http://www.datarius.com/) and Expert Magnetic Corporation (http://www.expertmg.co.jp/). Manufacturers and suppliers should be contacted for quotes.

8.1.11.5 Mid Range Quality Production Testers

8.1.11.5.1 At the time of writing the cost of these devices range from a US$ 3,000 to US$ 11,000 or more. These systems test all the required parameters using standard PC drives which have been specially selected and calibrated. It is recommended that before considering such mid priced testers, the prospective purchaser investigate thoroughly the types of drives and the accuracy of the device. It is also strongly recommended that all mid priced systems be regularly calibrated against a known standard. Currently, a major manufacturer of such mid range testers is Clover Systems (http://www.cloversystems.com/)

8.1.11.6 Downloadable Testers

8.1.11.6.1 There are a number of downloadable testers available online which use a computer’s inbuilt CD/DVD drive to measure error in written CD and DVDs. However, due to the limitations of the software and inaccuracy of the drives, most, if not all, are unsuitable for archival purposes.

8.1.12 Access and Data Migration

8.1.12.1 Discrete carriers like CDs and DVDs are not well suited for on-line access. Making a collection available necessitates staff handling the disks. Handling is one of the worst enemies of this kind of media. Always handle the disks by the edges, and always keep them in their enclosures when not played. The effect of light on the dyes are documented as a deteriorating factor, and excessive temperature and humidity must be avoided, as this may hasten degradation of the disk, and in extreme cases cause delaminating of the polycarbonate layers (Kunej 2001). The disks should be stored in acrylic jewel cases, and cheap plastic sleeves should be avoided as they may create an environment that is detrimental to the disk.

8.1.12.2 Copying for access purposes is however an easily undertaken task, and may be done at many times real time. There are jukeboxes on the market, which, with the appropriate software, will enable online access to the collection, though copying to hard disc may be preferable.